Hyundai can now build and deliver cars just six hours after an order is placed using factories that are minimally staffed, run by artificial intelligence (AI) and use robots to do the key manufacturing work.

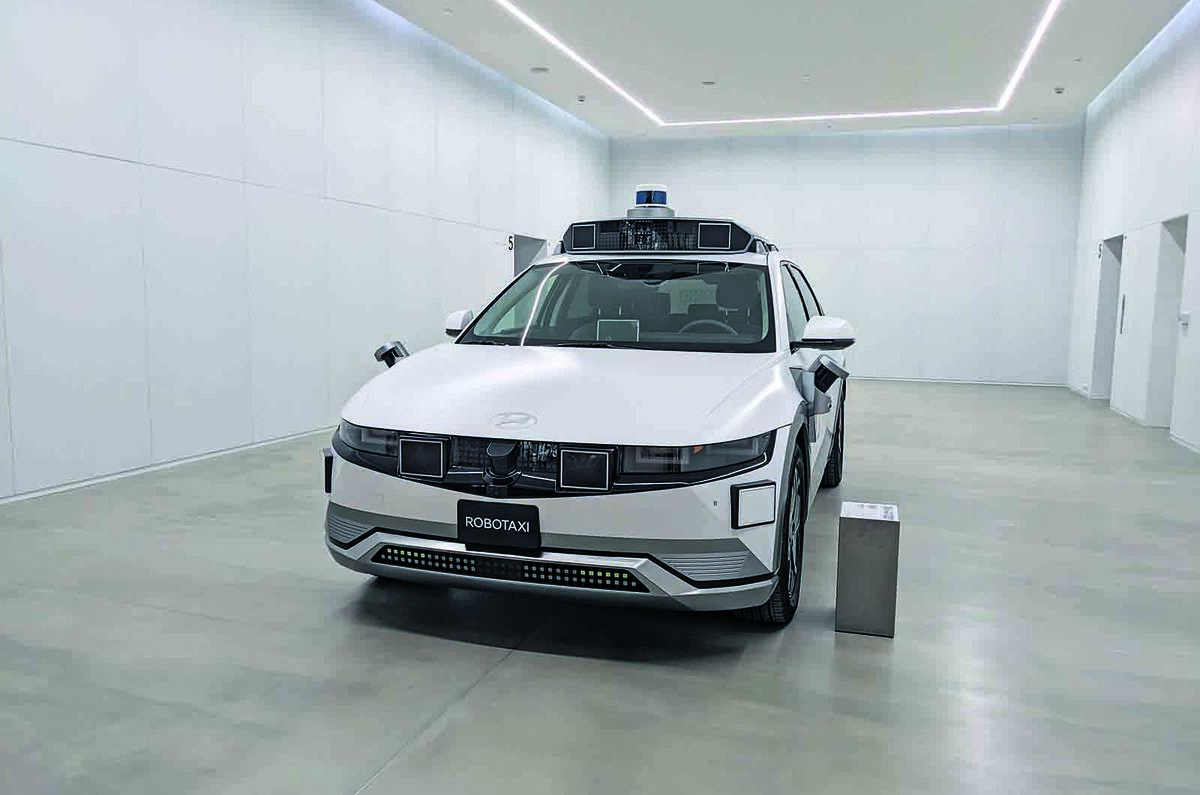

Showcased for the first time at the Korean brand’s new Innovation Centre in Singapore, this ‘Smart’ facility – currently producing the Hyundai Ioniq 5 and, from 2024, the Hyundai Ioniq 6 – will be used as a test bed for scores of similar sites that will pop up in cities around the world, with the UK not ruled out.

These new-era electric car factories will serve local urban markets, with a major focus on personalisation and customer experience, as part of a major push towards taking the brand upmarket.

“This isn’t just a factory: it’s a customer experience centre,” said factory boss Alpesh Patel. “Customers can interact with us in a close way.”

This process starts in the ‘Ioniq Lounge’, where customers create and order a bespoke Hyundai. (Some options will be exclusive to the site.)

They are then taken to a virtual reality suite to view a simulation of the car being created, before a screen rises to reveal the actual factory floor, and the actual car.

From there, they head to the site’s restaurant to eat produce grown on site at Hyundai’s robotically maintained Smart Farm, before watching the car be test driven on the factory’s roof test track, à la Fiat’s old Lingotto plant in Italy.

Finally, the completed car is delivered to the foyer by autonomous robots. Why this sudden push towards customisation? “When you look at the value proposition of personalising, it starts making far more sense to do it,” said Patel.

He added that a full “mass personalisation” offensive will be rolled out in the next few years to Hyundai’s wider line-up to capitalise on the growing trend.

AI to take the lead

The part-human, part-AI-powered workforce uses a meta factory (a digital twin) to run simulations for processing upcoming jobs, such as large shipments, to work out where to send robots at any given time and how many to deploy.

The goal is to allow the AI brain to take the lead on both day-to-day operations and future planning, in tandem with a human counterpart based in a digital command centre.

Add your comment