One way of improving the performance, efficiency and emissions of a combustion engine is to take better control of its breathing.

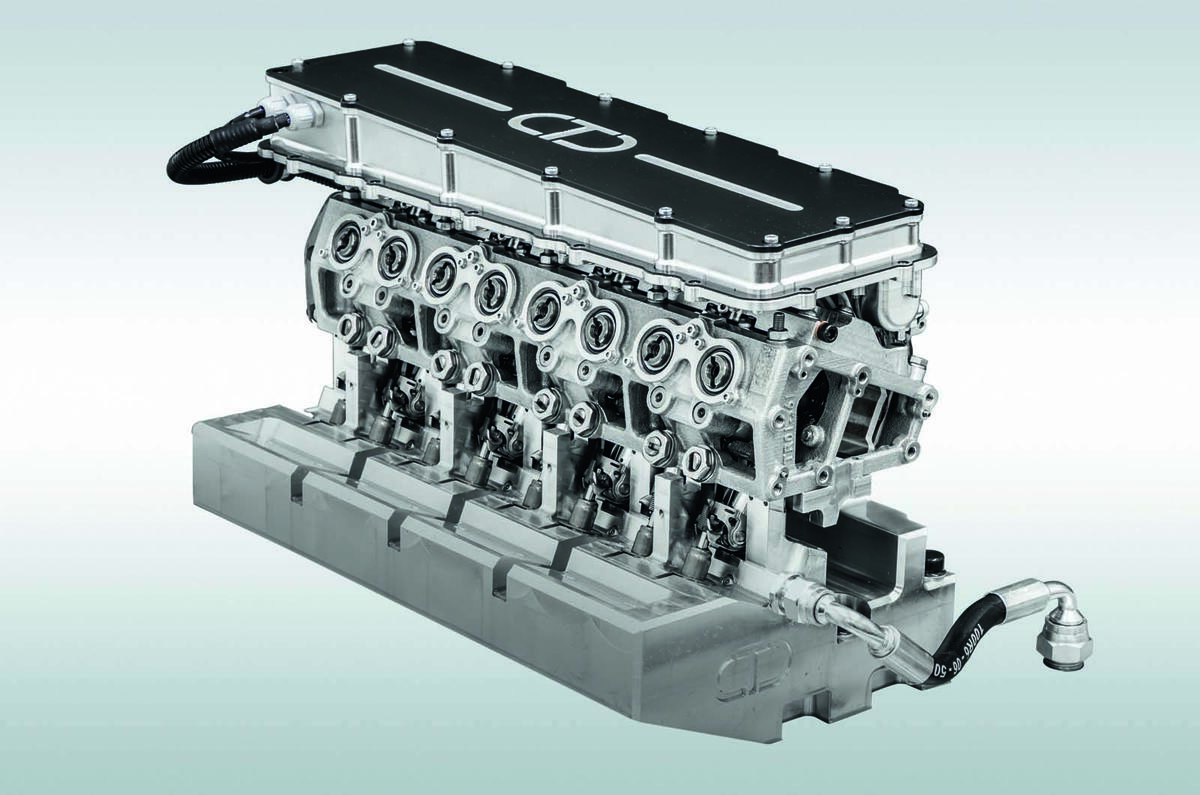

Autocar first looked at the intelligent valve technology (iVT) system from British company Camcon in 2017, and now a single-cylinder version, called Single Cylinder Intelligent Valve Technology (SCI), has been adopted by Brunel University London’s Centre for Advanced Powertrain and Fuels (CAFP). CAFP will use it for advanced combustion research.

So what does iVT do? A basic valve train has no variability when the engine is running. Valves are opened by cams on a shaft and usually closed by a spring. It is impossible for an engine to be well-mannered and flexible to drive at low revs and give its absolute best in the power stakes at high revs, so there has to be a compromise between the two. Variable cam timing (phasing), lift and now the duration of valve opening (see Hyundai’s new CVVD system) are all in play, but the ideal would be to have complete control of each valve independently of the engine crankshaft.

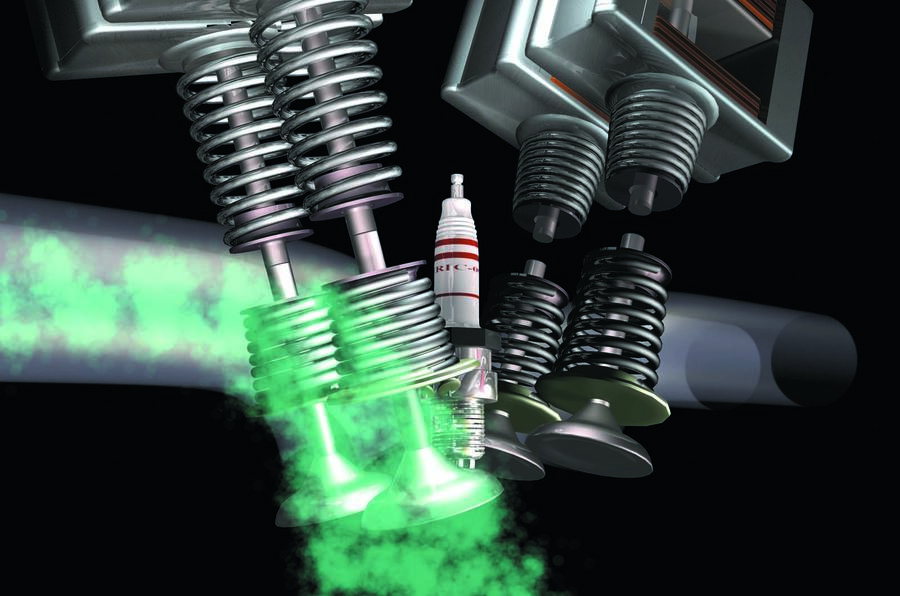

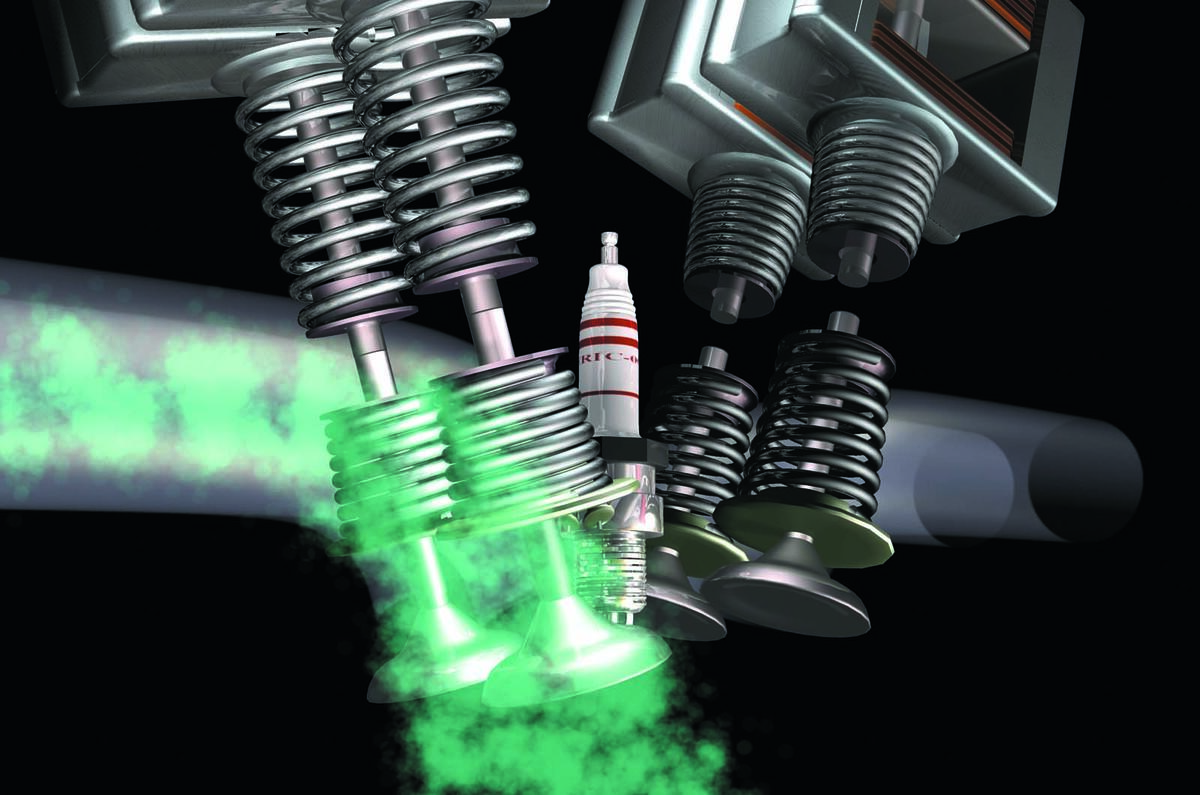

What iVT does is replace ‘one for all’ camshafts with separate opening and closing mechanisms for each valve. Many ‘camless’ technologies have been tried in the past, some wackier than others and usually replacing cams with electromagnetic solenoids, but so far no solution has made it to production. Camcon’s system retains cams, but one for each valve, mounted across the cylinder head rather than lengthways and driven by electric actuators rather than a chain or belt from the crankshaft. The system replaces the traditional camshaft of a conventional engine with a digital one, giving each valve the freedom to potentially do what it likes.

The three separate functions of timing, lift and duration of lift (how long the valve stays open) are rolled into one, but iVT goes further. Both the inlet and exhaust valves can be moved at any point in the four-stroke cycle, allowing minute control of the engine’s breathing. So accurate is the system that even the way a valve opens and closes can be changed on the fly. For example, the point at which maximum lift is achieved can be varied, earlier or later in relation to the piston’s position in the cylinder. The valve can be lifted very rapidly, then held at the desired amount of lift (which in turn is variable), then closed equally quickly. Alternatively, the valve can be lifted slowly then accelerated the last bit to maximum lift before closing again.

Minutely variable control like this couldn’t be achieved with conventional valve springs, so the Camcon system is ‘Desmodronic’, meaning valves are closed mechanically as well as opened, meaning there are no valve springs. The system is a real breakthrough and has been trialled successfully on a 2.0-litre Ingenium petrol engine in a Jaguar XF, but it can be applied to any piston engine running any type of fuel and with any number of cylinders.

Renault’s early iVT

Join the debate

Add your comment

Stay of execution...?

So this is good?, well yes, it’ll keep ICE cars on the Roads for a little longer to EV is the norm.