Rising levels of CO2 might be the biggest threat to life on Earth, but it’s by no means the only man-made environmental problem the planet faces.

Waste plastic is constantly in the news and many argue that instead of shovelling it into landfill sites, why not recycle it into clean hydrogen fuel that’s so pure it can be used to power road transport, including cars?

According to Hydrogen Utopia International (HUI), 368 million tonnes of plastic is produced annually. A relatively small amount of that is recycled or disposed of in a responsible way and production is expected to double by 2030 and increase by a factor of fi ve by 2050. Enter British company Powerhouse Energy Group International and its DMG (Distributed Modular Generation) technology, which HUI has licensed for exclusive use in Hungary, Poland and Greece and non-exclusive use in the rest of the world. Powerhouse says that where plastic can be recycled into other plastics, it should be, but contaminated plastics can be difficult and expensive to recycle and there are limits to the number of times it can be done.

DMG is a thermal conversion process that turns waste materials into gas by exposing them to intense heat but not in the presence of oxygen (pyrolysis). In this case, mixed and shredded but not necessarily clean plastic waste that would otherwise be headed for landfill is added to a chamber heated to around 1000deg C, where it instantly melts and ‘gasifies’. Oxidising agents are added next and the resulting chemical reaction produces synthetic gas or ‘syngas’, containing some carbon monoxide and CO2, methane (natural gas) and hydrogen. Once the high temperature chamber has been started up using natural gas, a small amount of the syngas gas it produces is used to power it.

Syngas can be burned in gas engines and, in that form, 25 tonnes of shredded plastic can be used to generate 2.8MWh of electricity, but the preference is to separate the hydrogen from it using another process. In its raw state, the hydrogen contains impurities such as tar, preventing its use in fuel cells, for example. A final step cleans up the hydrogen and the finished product is 99.999% pure. There are by-products, including a small amount of inert ash (equivalent to 5%-10% of the original feedstock material) and a hydrocarbon-rich paste that can be used by refineries.

HUI is planning a flagship plant at Konin in Poland and approval by the authorities to start work is expected by the end of this year. HUI production units will be capable of producing 2.7 tonnes of pure, road-fuel-quality hydrogen from 40 tonnes of plastic waste. Only 1.5 hectares are needed for a plant (about the size of 1.5 rugby pitches) and the company says its units can easily be bolted on to existing waste disposal plants.

Instant puncture repairs

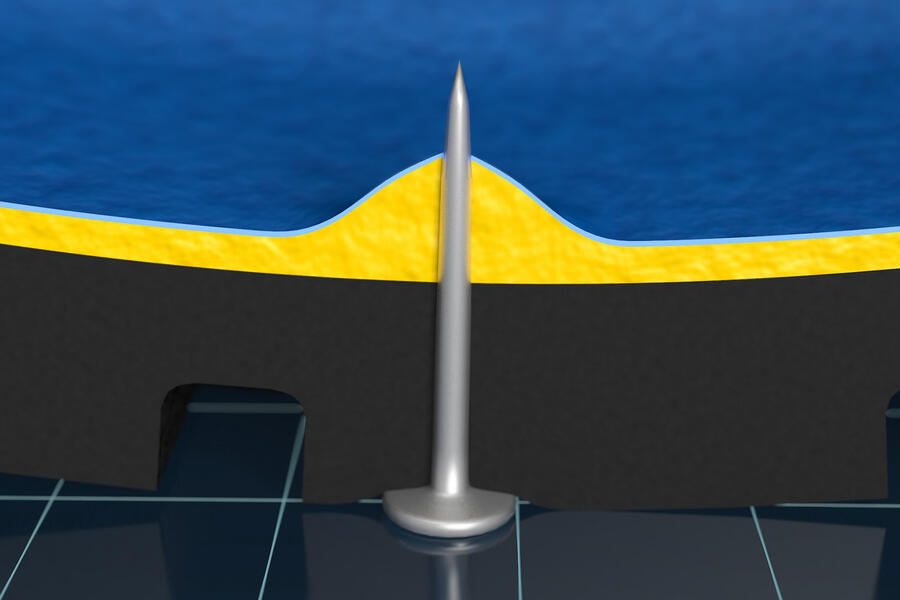

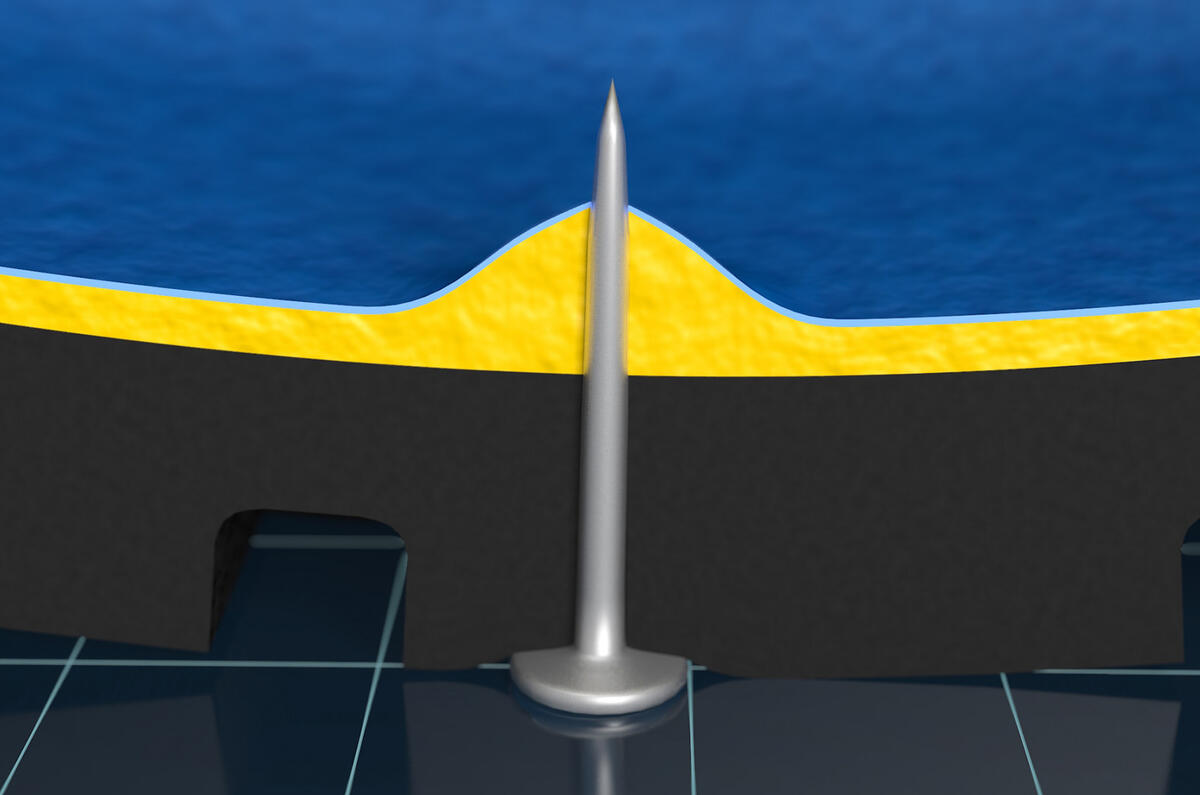

Michelin Selfseal repairs a puncture instantly thanks to a millimetres-thick layer of sealant, based on natural rubber, that is used to coat the inside of the tread. As a sharp object such as a nail penetrates the tyre, the tyre pressure forces the sealant against the puncture, stopping the escape of air inside the tyre. If the foreign object is removed, the sealant covers the wound.

Michelin Selfseal repairs a puncture instantly thanks to a millimetres-thick layer of sealant, based on natural rubber, that is used to coat the inside of the tread. As a sharp object such as a nail penetrates the tyre, the tyre pressure forces the sealant against the puncture, stopping the escape of air inside the tyre. If the foreign object is removed, the sealant covers the wound.

Join the debate

Add your comment

And still the idiots refuse to accept that the future is a hydrogen society! It's hilarious!!!

Syngas is nothing new, its been around for a century. In the past it was made from coal and the syngas was known as town gas and was used to heat our homes before natural gas displaced it. Its a nice mixture of methane, carbon monoxide, carbon dioxide, hydrogen and other hydrocarbons. It can be made from any hydrocarbon source like methane, wood and in this case plastic. All this DMG process has done is a bit of green washing by separating and purifing the hydrogen in it and claiming it can be used for FCEVs. In the meantime the bulk of the syngas produced will be burned or further steam reformed to make brown hydrogen both processes of course producing large amounts of carbon dioxide. Lazy journalism from Autocar who again regurgitate a press release from a vested interest without even spending 5 mins on Wikepedia.

What is it with auto car and the hydrogen lobby. It's over the BEVs won the day.