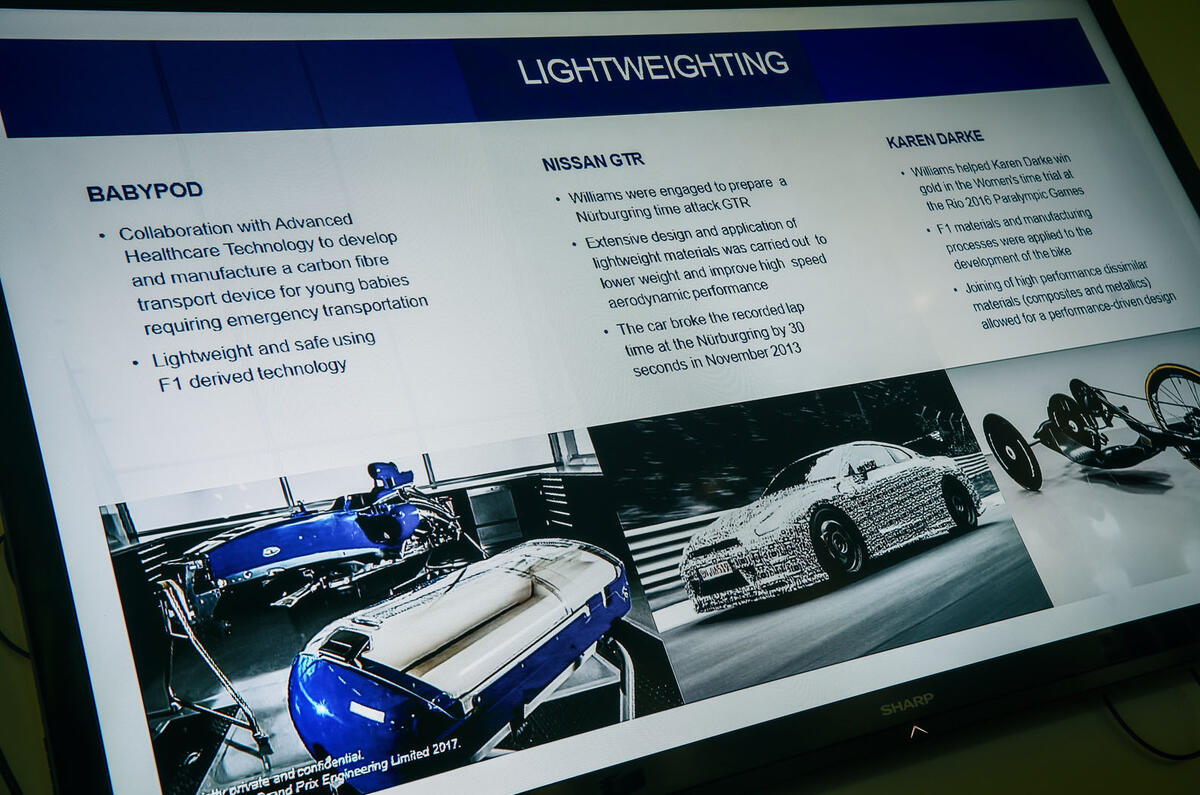

A new composite chassis concept, aimed at showing car makers an efficient way of changing from petrol to electric cars, is being launched today at the Cenex LCV show by Williams Advanced Engineering (WAE).

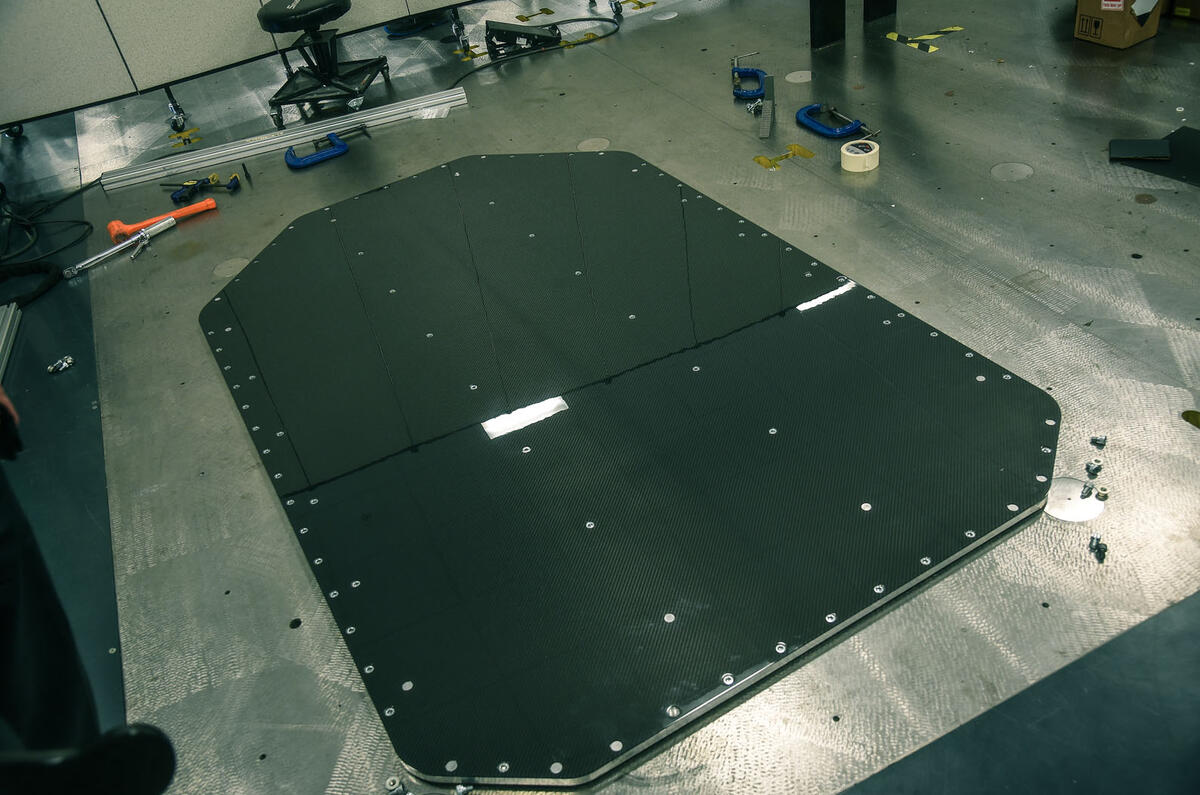

The new concept, dubbed FW-EVX, shows how car makers can create all-new plug-in hybrid or full-electric models without going through the comparatively inefficient stage of building electrified versions of conventional cars. FW-EVX is a highly optimised all-electric rolling chassis

—in effect, a scalable and self-supporting ‘skateboard’. It uses a rigid and compact composite structure to carry electric motors (up to four),

to mount traction batteries

in a low and safe location,

to manage airflows for both component cooling and aerodynamic efficiency and to provide mountings for new, Williams-designed carbonfibre suspension parts.

Other so-called skateboards have been proposed in the past, but none capable of handling so many competing car functions at once, or with such scalable versatility built in. The concept could work, Williams engineers claim, for both composite and aluminium construction.

According to Craig Wilson, WAE’s managing director, the FW-EVX concept can make an EV lighter, safer and greener than a conventional adapted design. Its space efficiency allows it to carry a bigger battery, for a longer range and better performance.

The whole system, subject to Williams patents, has been configured for maximum adaptability, allowing clients to fit it with a wide range of ‘top hat’ bodystyles. “We believe there’s a business with high potential here,” said Wilson.

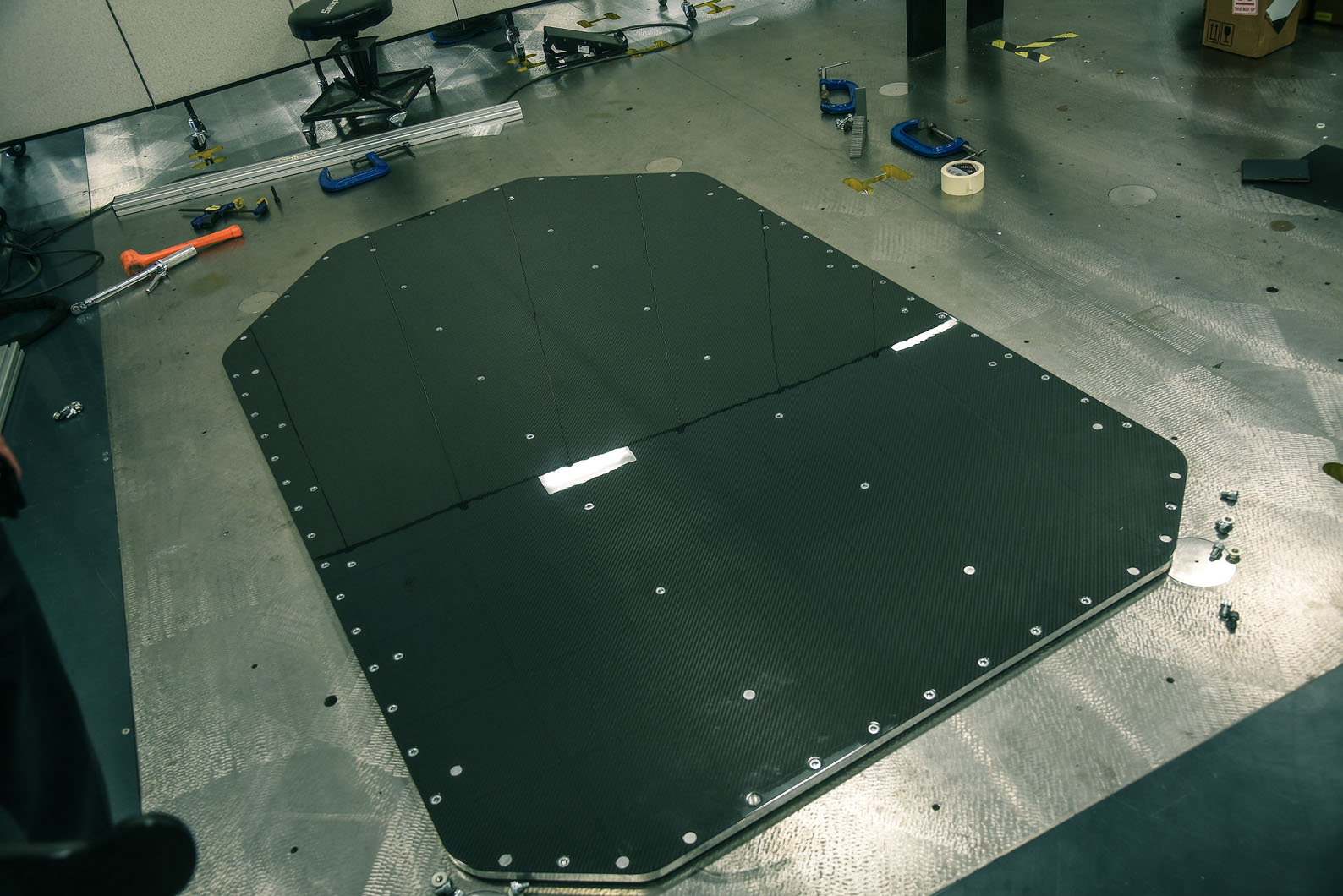

In effect, FW-EVX consists of a rigid central platform with latest-spec crash structures mounted front and rear. It carries a long, wide but thin under-floor battery box in its centre. The box is enclosed by a pair of hollow, load-bearing composite members, forming sills at the edges. They collect air at the front of the car, direct it through alloy radiators mounted inside, and exhaust it rearwards in a way that can create downforce via an aerodynamic diffuser.

Two tech highlights in more detail

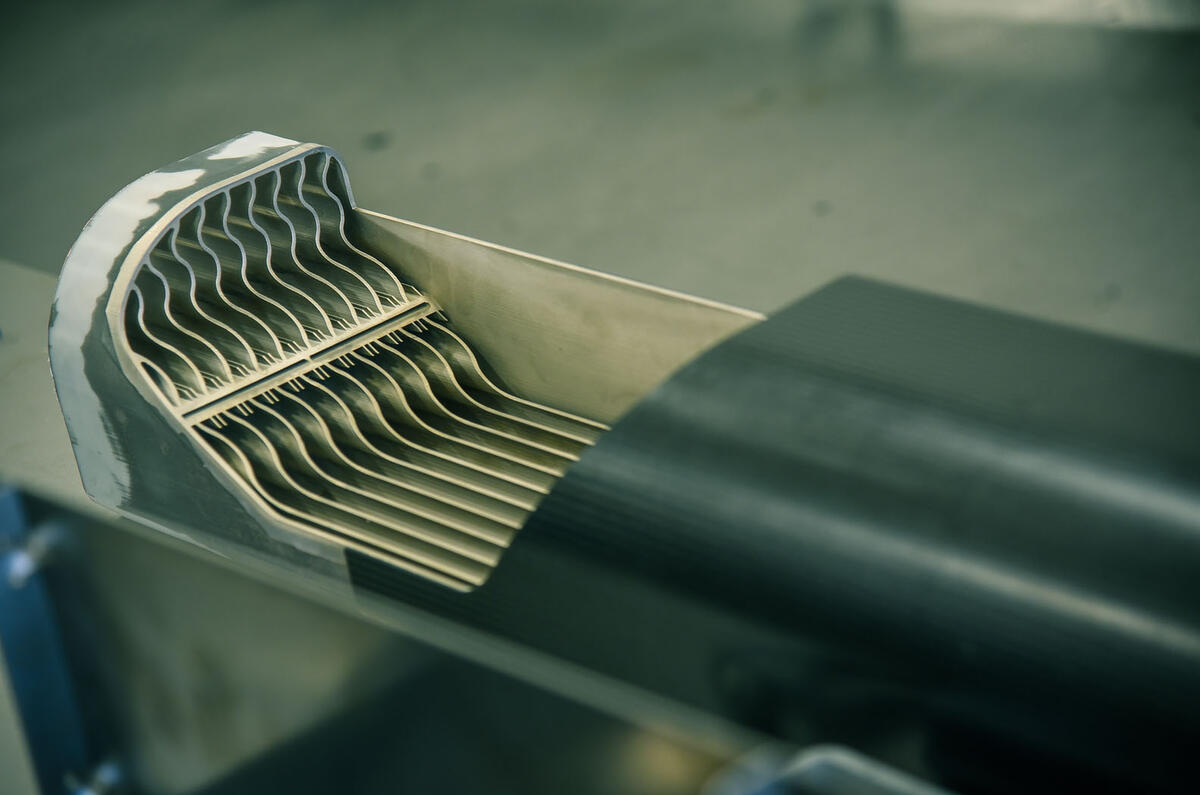

Flat-pack battery module:

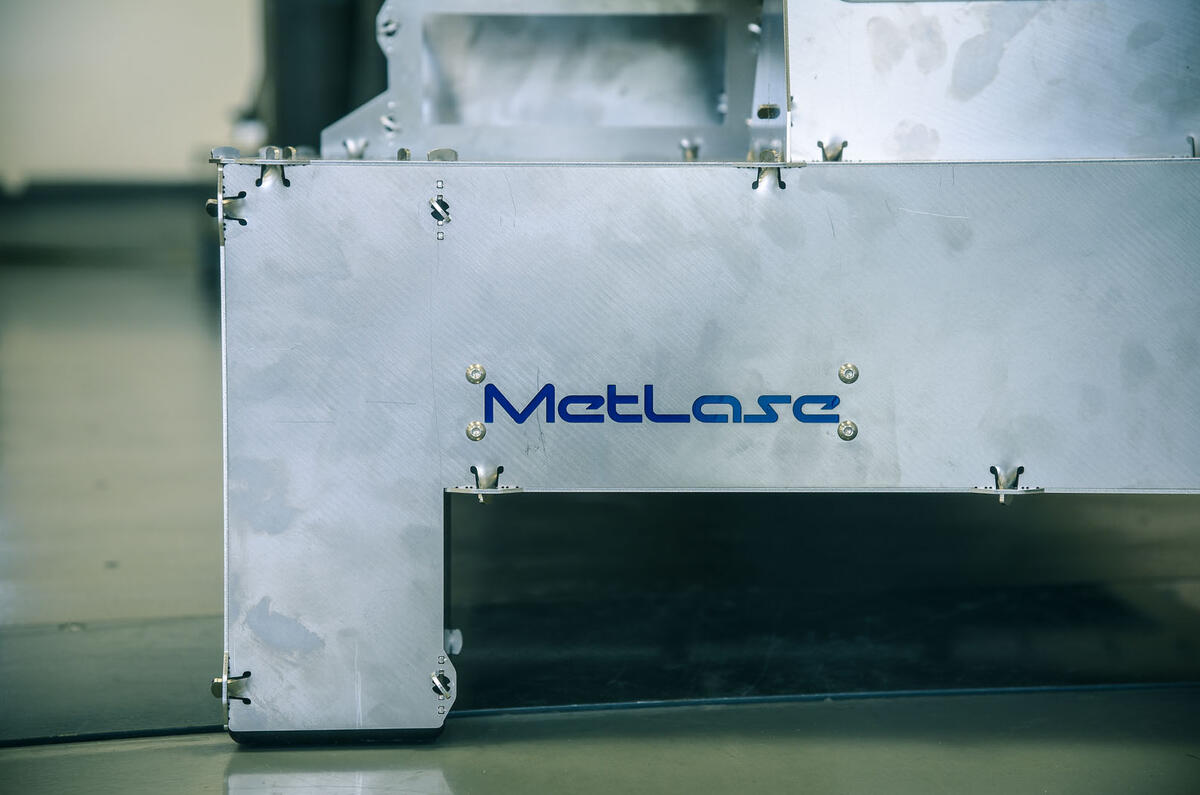

Williams’ new concept chassis also showcases a rigid composite battery pack design, made by a process it calls ‘223’ because it starts in two dimensions as a sheet of material but eventually forms a skeletal, compact but extra-strong 3D component. FW-EVX’s central battery module — its outer carrier etched into components

as a sheet, then folded and bonded into its final form — is strong enough to contribute to the rigidity of the total system and to protect it very effectively in a crash. Formed in carbonfibre, it’s also extremely light.

Join the debate

Add your comment

Hi, steve Cropley Great post buddy. I hope you will continue to write more helpful posts like this one for us in the future. Learned quite a bit.

Like a Tesla

There is one pretty much like this in just about every Tesla showroom and has been for years.

I'll have mine as a 2+2 (need space for the dog)

More integrated and almost certainly a lot stiffer and lighter than the MEB platform (TEB platform?), so probably aiming a little higher up the food chain than as a replacement for the Golf and its clones.