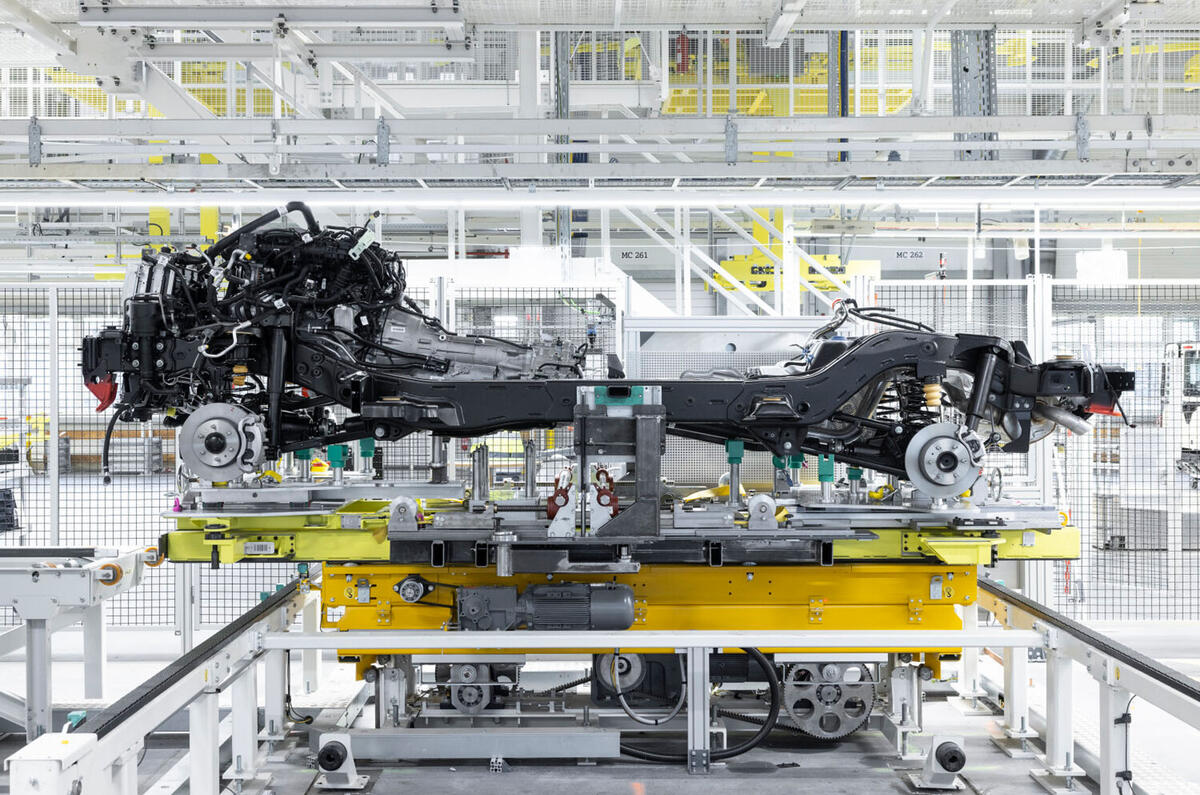

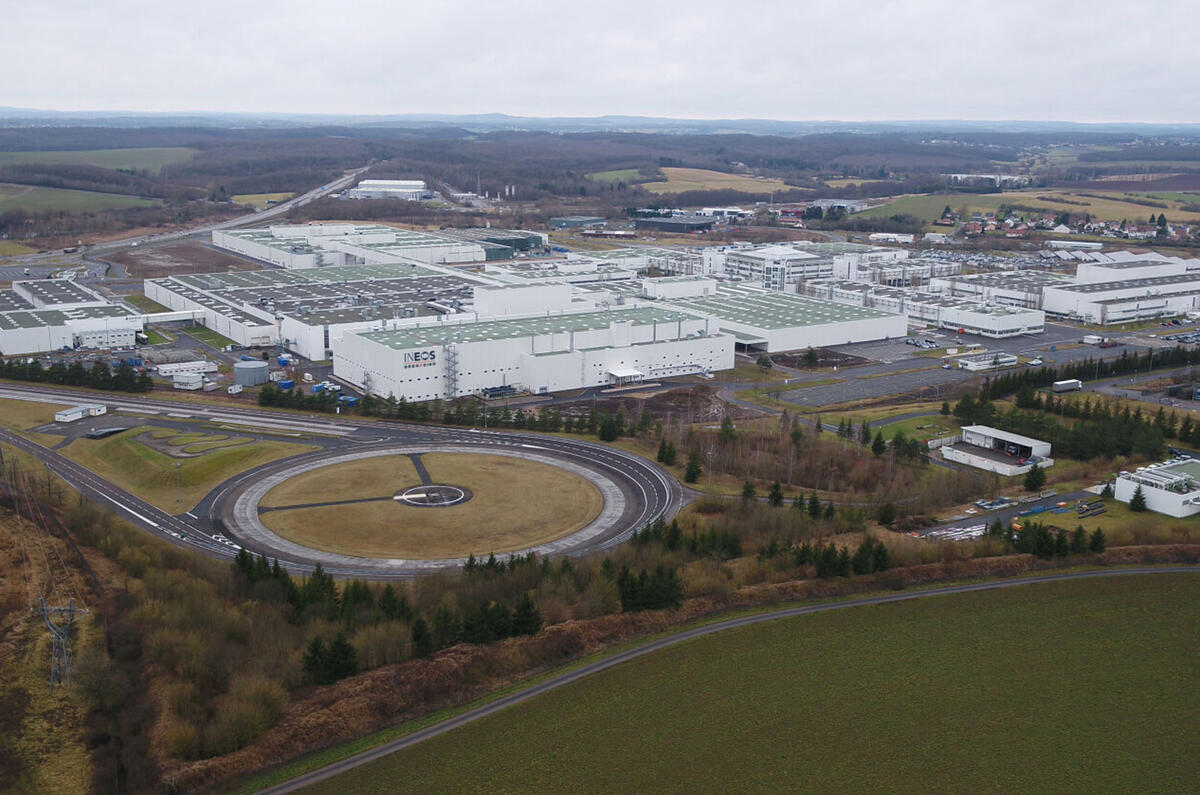

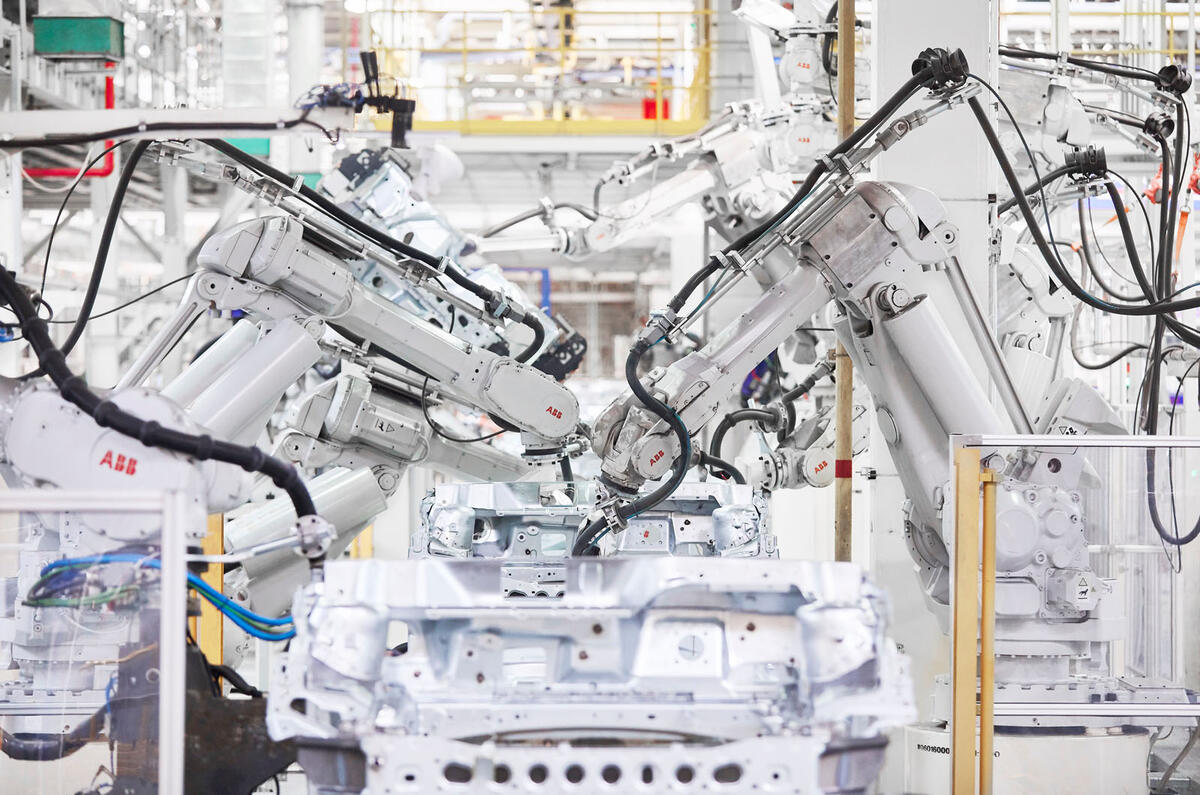

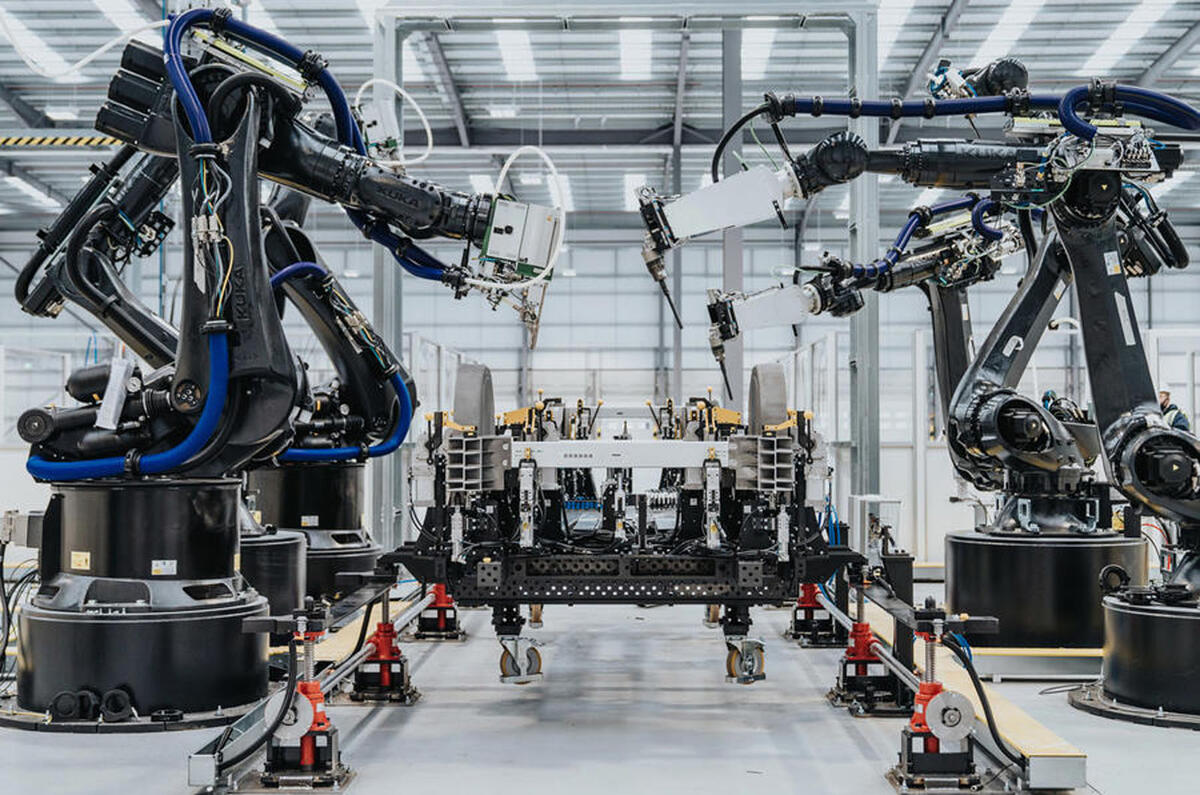

Disruptors are demonstrating that legacy car manufacturers don’t necessarily have all the answers and that includes where car factories are concerned. When it comes to how to build a car, the big OEMs are ploughing billions into expanding their existing facilities, but there are alternatives. The microfactory is not a new concept but has become popular recently with start-ups such as Arrival, while Ineos has forged a different path and effectively taken over the old Smart Hambach factory, using the brownfield site to build the new Grenadier.

Erik Torseke, director of operations and supply chain for Ineos Automotive, and Peter Wells, pro-dean of public value at Cardiff Business School, joined us for an in-depth discussion about the future of car manufacturing.

Add your comment