The new Audi SQ7 SUV has been revealed at the company's Ingolstadt headquarters in Germany.

Significantly, the latest addition to the Audi Q7 line-up is the first series production car to receive an electric powered compressor to boost the performance of its engine – a new 429bhp 4.0-litre V8 diesel also destined for the fourth-generation Audi A8 and a new Q8-badged range topping SUV, both already under intensive development at the German car maker.

In a first for Audi, it also uses electro-mechanical active roll stabilization system to suppress roll during cornering as well as a 48-volt electric sub system in combination with the existing 12-volt electric system used on other new second-generation Q7 models.

The SQ7 TDI is the first Q7 model to receive the “S” treatment, following on from the Audi SQ5, which has been on sale in the UK since 2013. Pricing will start from around £70,000, and officials confirm it is planned to head into UK showrooms at the end of 2016.

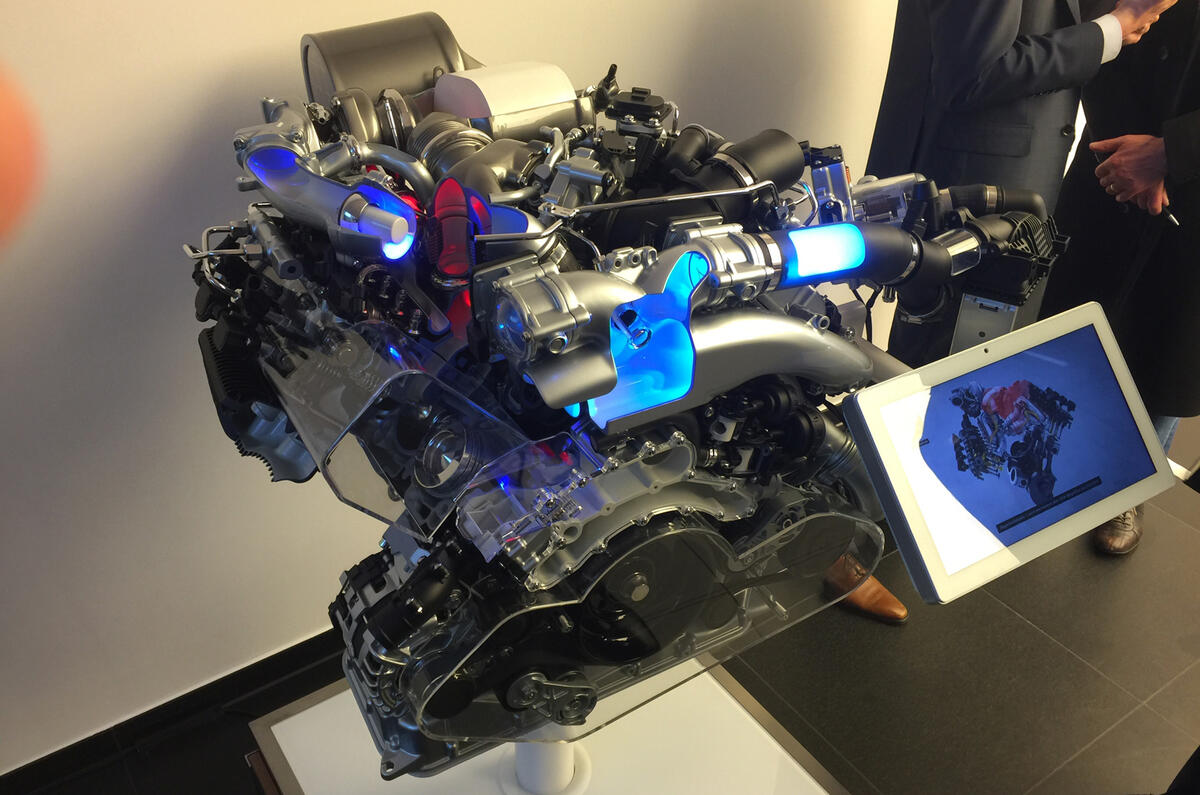

Heading the list of developments brought to the SQ7 TDI is an all-new diesel engine. With a swept volume of 3956cc, its overall displacement is 207cc smaller than that of the unit it replaces in keeping with current downsizing trends. It also adopts a new common rail injection system that generates up to 2500bar of injection pressure as well as Audi’s patented valve lift system – the latter marking the first time it has been applied to one of the German car maker’s diesel engines.

In a move similar to that of rival BMW and the most powerful version of 3.0-litre in-line six-cylinder diesel, the new Audi unit uses three chargers to boost induction. But whereas the BMW powerplant relies on three conventional exhaust gas driven turbochargers, the new Audi engine receives two exhaust gas driven turbochargers and a separate electrically driven compressor in what the German car maker is billing as a world first for a series production car.

The two exhaust gas driven turbochargers, mounted within the 90-degree angle of each cylinder bank to provide them with short flow paths, run in a sequential process, with the smaller turbocharger engaged at low and intermediate throttle loads and the second larger turbocharger activated at higher loadings. The electrically powered compressor, or EPC has commonly referred to, augments the efforts of the turbochargers by increasing the throughput of air within the induction system at lower low throttle loads in a bid to improve overall response.

Modern day diesel engines tend to drop their revs quite markedly when you back away from the throttle as result of the induction pressure being dramatically reduced as the boosting effect of the turbochargers is halted.

The idea behind the new induction process applied by Audi to its new V8 is to use the additional air forced into the induction system by the EPC, whose compressor wheel spins at up to 70,000 rpm, to keep the smaller turbocharger primed and ready to spin back up to its maximum boost pressure as fast as possible so that full torque is available virtually the moment you get back on the throttle.

“The electrically driven compressor in the SQ7 TDI is a world first, with which Audi underscores its claim Vorsprung durch Technik,” said Stefan Knirsch, member of the AUDI board responsible for technical development.

Join the debate

Add your comment

Or should the Grill be larger

Has the 48v anti-roll system

Deutsche Qualität !