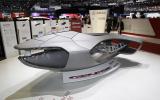

The Edag Genesis previews a new production method its maker hopes will reduce the costs of new cars and offer huge potential for vehicle customisation.

The technique developed by OEM supplier, Edag is effectively a 3D printing technique. Although the Genesis previewed at the Geneva motor show is a monocoque shell, the firm wants to start by producing smaller components.

Bosses expect parts such as 3D printed rear view mirrors could become a production reality within two years. From there it hopes to develop techniques to build a dash panel within five years, structural components by 2030 and entire monocoques by 2045.

Edag says the clean and quiet tooling-free production process, minimal waste, cheap materials will drive down costs. It requires new production methods, such as selective laser welding which can bond composites as well as metals.

In time, the technique could be used to produce customised components for customers. Car buyers could upload their own designs, have them printed and fitted to their own car.

Dan Stevens

Join the debate

Add your comment

3D printing