"Whenever we say to people we work at Dennis Eagle, they say: 'Dennis? Oh, the fire engines."

As reputations go, you could do worse than be associated with producing emergency response vehicles, but if you haven't actually had anything to do with them for more than two decades, and have since become a market leader in quite another area, the misconception is probably a bit frustrating.

"It wasn't us that manufactured the fire engine. We manufactured the cabin at our plant in Blackpool, yes, but it was in 2004 they stopped manufacturing it," explains the company's managing director, Keith Day. "We've got thousands of these driving around the streets now that seem to be invisible," he says, gesturing out of the window of the firm's Warwickshire factory at the ranks of gleaming new bin lorries awaiting delivery to their new owners.

Dennis Eagle, like all the very best automotive-adjacent institutions (cough), was started in 1895, originally as Dennis Brothers, a maker of lawnmowers and bikes that later branched out into building chassis for a wide range of commercial vehicles, including - you guessed it-fire engines.

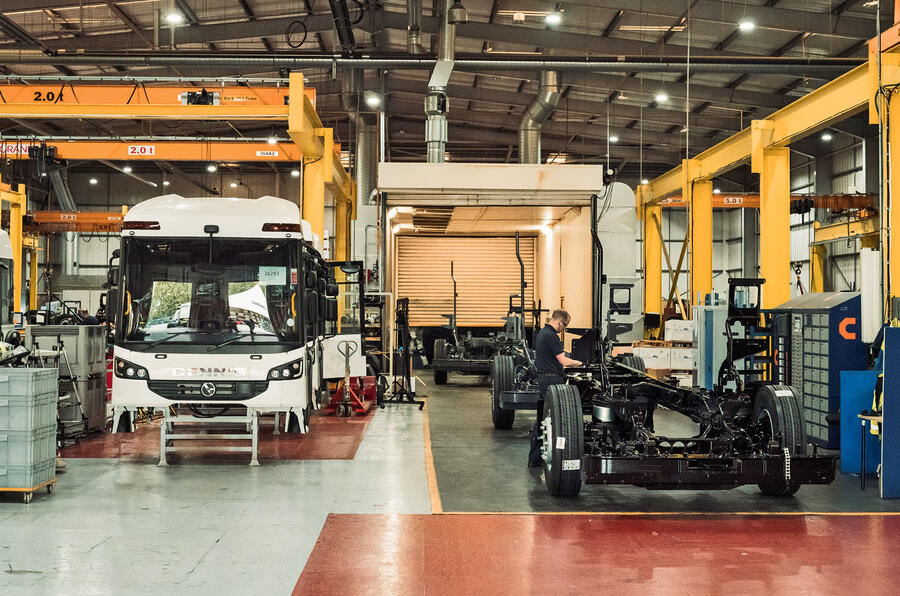

Today's company was formed in the mid-1980s when Dennis merged with vehicle body manufacturer Eagle Engineering and opened a factory in Leamington Spa, which over the past four decades has grown to become one of the country's most important vehicle plants.

The site currently produces roughly 32 lorries a week of various shapes and sizes - mostly derivatives of Dennis Eagle's own Elite and electric eCollect models, but the firm is more than happy to plop one of its bodies on the back of a chassis cab from Mercedes, Volvo or Scania, some of its biggest rivals in the sector.

The company builds almost everything in the UK, where it employs more than 1000 people - and the domestic market is its biggest, accounting for around 80% of its total output.

Join the debate

Add your comment