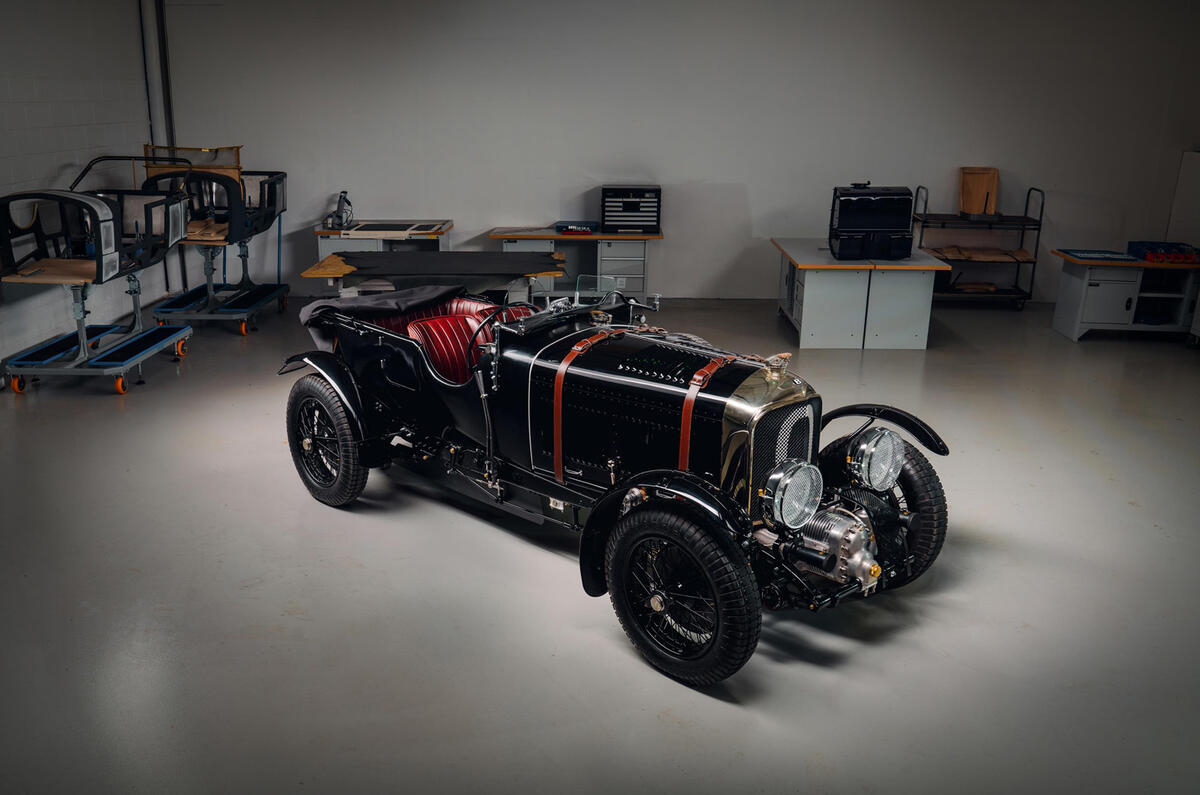

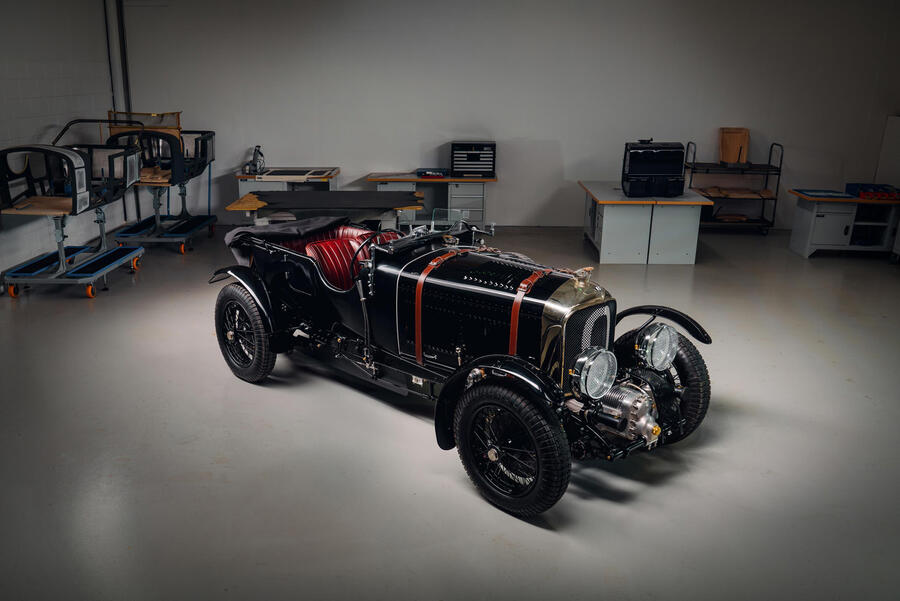

You might not have heard of the Envisage Group – but you’ve almost certainly seen some of its work. Envisage has been responsible for the design, engineering and production of everything from gleaming motor show concepts and production-previewing prototypes to comprehensively re-engineered road-legal cars and one-off bespoke creations. They just might not be able to tell you about it.

The firm – established in 2009 and now encompassing four distinct divisions, four sites in Coventry and two international offices, in India and the US – has quietly grown into an industry leader in the expanding market of coachbuilding: creating limited-volume cars, either through the use of a bespoke platform or extensively reworking a donor vehicle.

Although a large stack of non-disclosure agreements prevents Envisage from revealing many of the projects it has worked on, they include static motor show concepts for major car firms – also known as OEMs within the industry – and a working pre-production prototype of a future electric supercar. Other assignments encompass production and engineering commissions for smaller design firms, and one-off or limited-run projects for enthusiasts who simply want to design their own dream car. Given the inexorable rise of coachbuilding in the car industry, Autocar asked Envisage to talk us through the process of turning a loose idea into a fully fledged machine.

The starting point

By definition, no two coachbuild projects are the same, with huge variance in timescale, budget, ambitions and expectations. So the first task is to work out the starting point and the expected outcome in order to understand the scope of work involved in the project.

Those starting points can range from a true blank sheet of paper to a complete design that a car maker needs turning into a proof-of-concept one-off working show car.

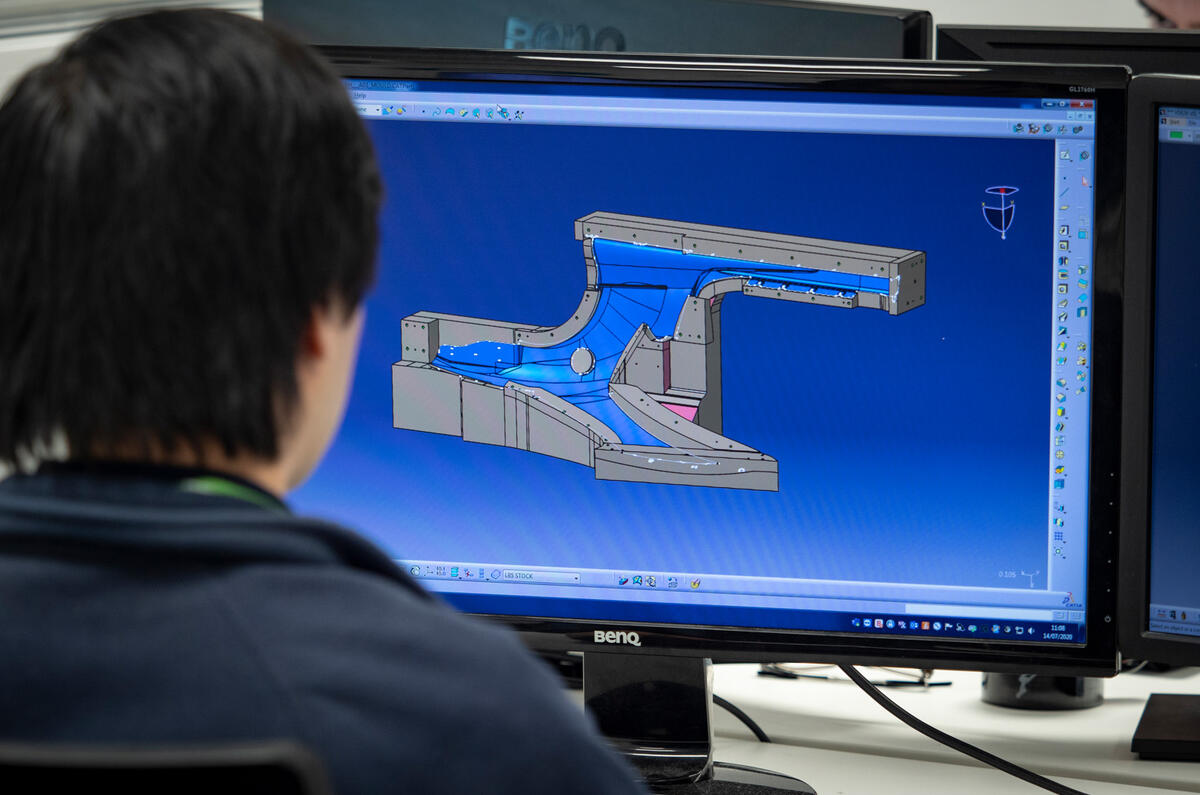

Designs will generally start with sketching out rough ideas or producing mood boards – collages of pictures that hint at the desired style and themes of the vehicle. Those designs are then refined using digital rendering software. Even with a blank-sheet-of-paper design, there will be some constraints in the form of hard points – set design elements for engineering, safety and so on.

“We’ve got different aspects to the business, from pure coachbuild to working out how to build a concept vehicle for a client, or turning a full design into a working concept,” says Envisage CEO Tim Strafford. “If it’s pure coachbuild, a client will come to us with an idea, and we’ll work with them to create a sketch. That will then go to our design team to start working on renderings.”

Add your comment