When it comes to Tesla, attention is usually focused on its production struggles, the latest actions of company founder Elon Musk or, from a technology perspective, its pure-electric powertrains. But with the Model 3, the firm is also aiming to pioneer a new approach to chassis and suspension design.

Tesla’s approach to designing those areas, which are crucial elements in defining a car’s character and desirability, didn’t follow usual automotive industry practice for volume car production. Autocar spoke exclusively with a number of Tesla engineers to gain an insight into that development process.

Most manufacturers these days build major new models from a platform or architecture, but when it came to the design of the Model 3’s chassis and suspension, Tesla engineer stuck with a ‘first principles’ clean-sheet approach. The starting point were the tyres, which Tesla describes as the unsung heroes of its cars and crucial to feel and drivability. Development started in 2015 and Tesla worked with tyre manufacturers for almost three years, which is longer than the time spent on the Model S’s tyres.

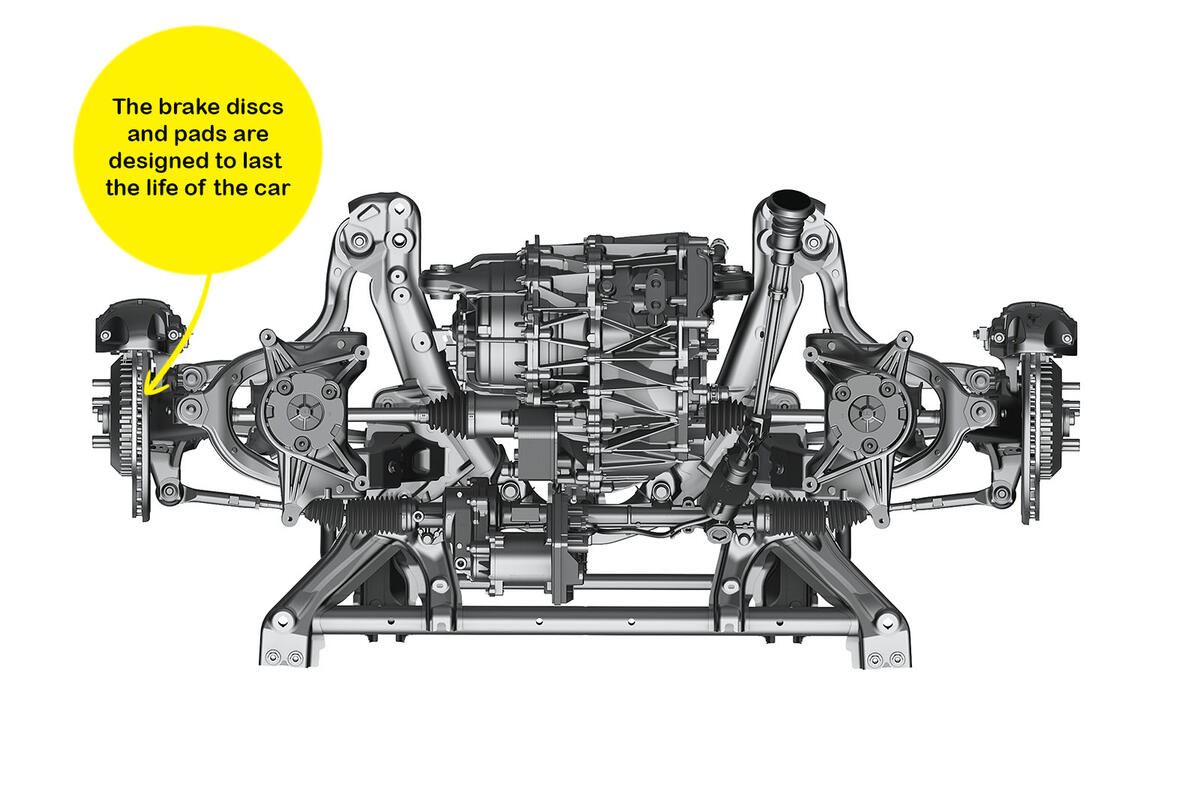

Tesla says tyres for a high-performance electric vehicle are challenged in a way that those on a car powered by an internal combustion engine (ICE) are not. A two-wheel-drive Model 3 with a long-range battery weighs just over 1700kg, so tyres have to cope with high loads as well as a 155mph top speed (for dual motor versions) plus continual torque input, either when accelerating or during regenerative braking.

The bulk of mass of an EV is usually located lower than in an ICE-powered car due to the battery packs being mounted under the floor. As a result, there is less vertical force build-up through the outside pair of tyres to generate grip when they corner. To tackle that, Tesla focused on tread stiffness, developing new compounds to deliver the desired combination of cornering grip and low rolling resistance. The tyres are filled with sound-absorbing foam to suppress noise amplified inside the tyre cavity.

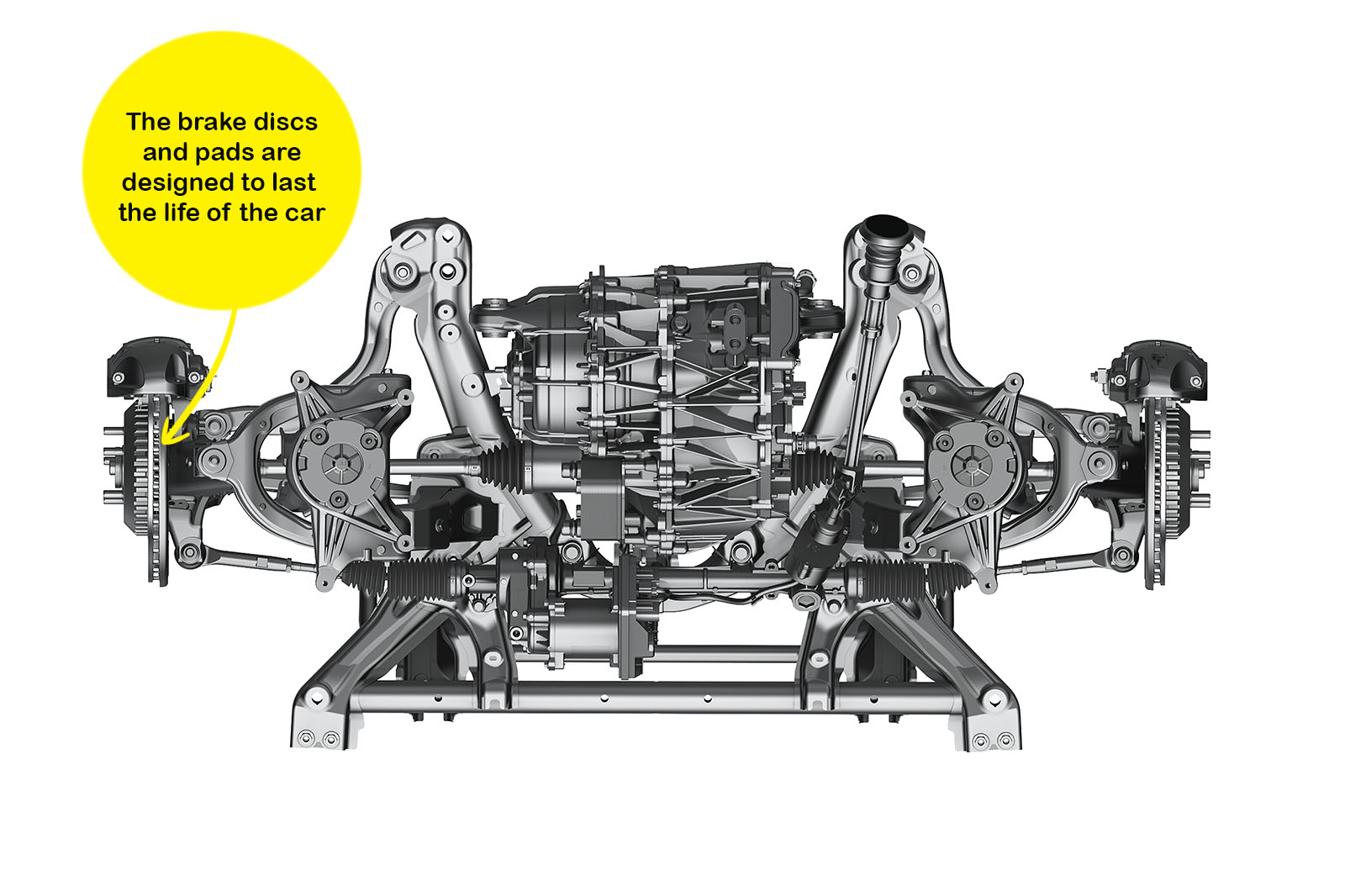

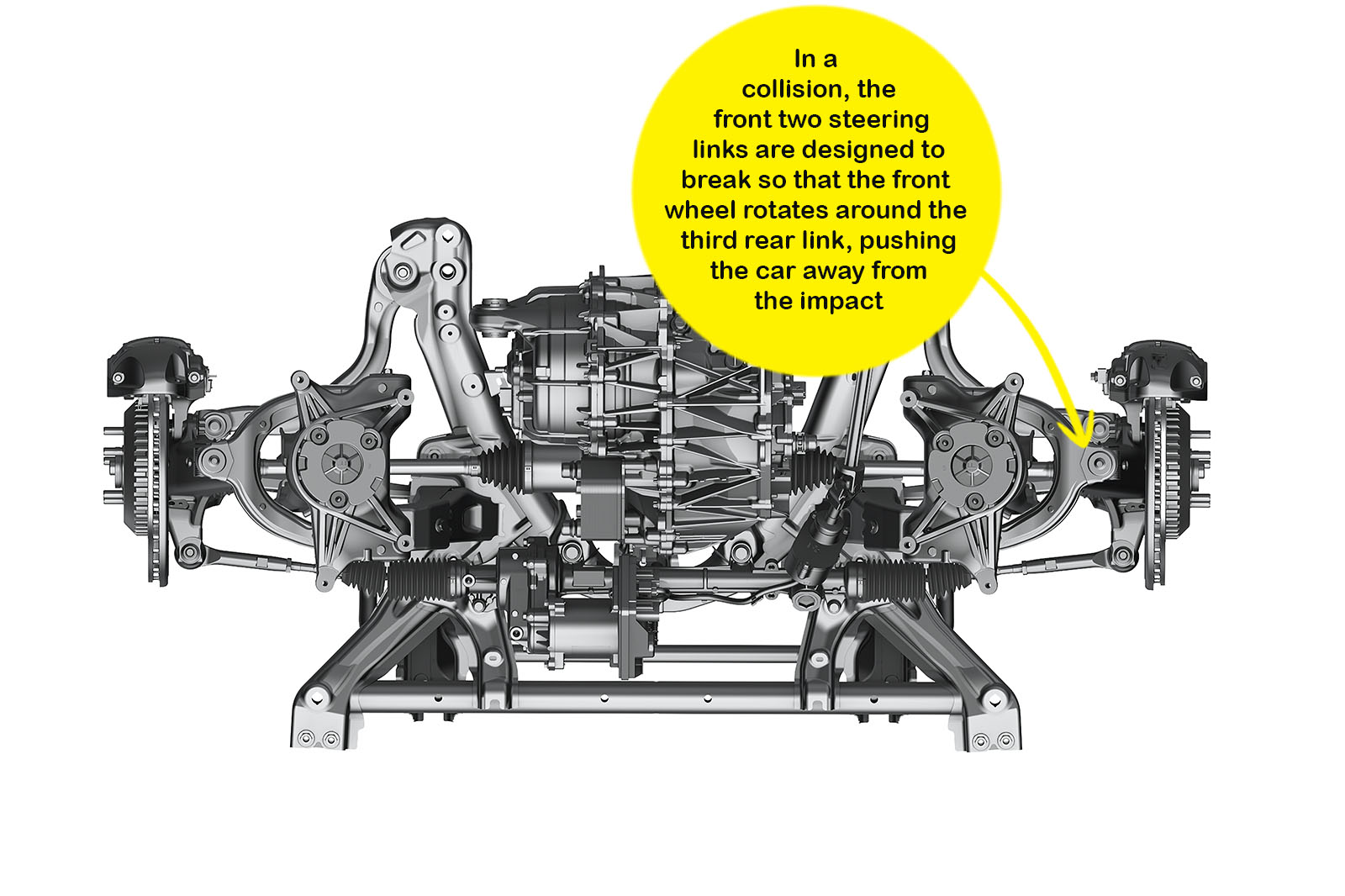

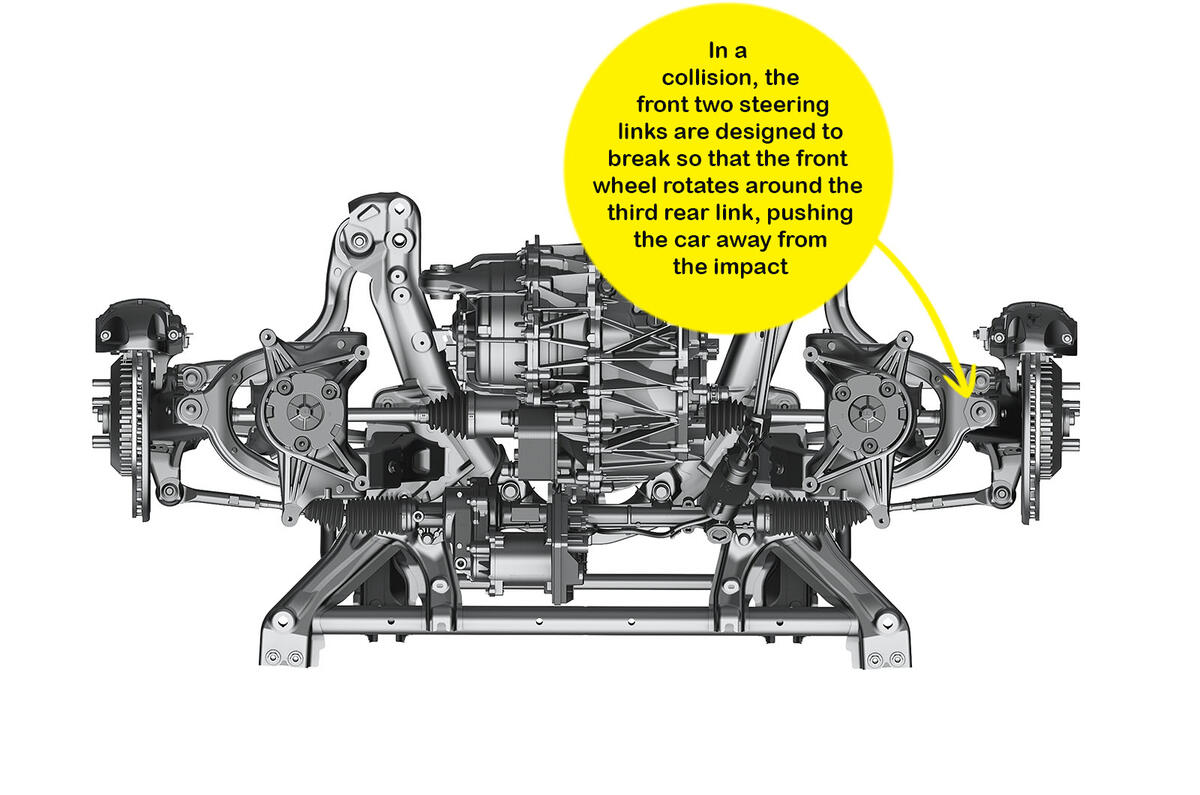

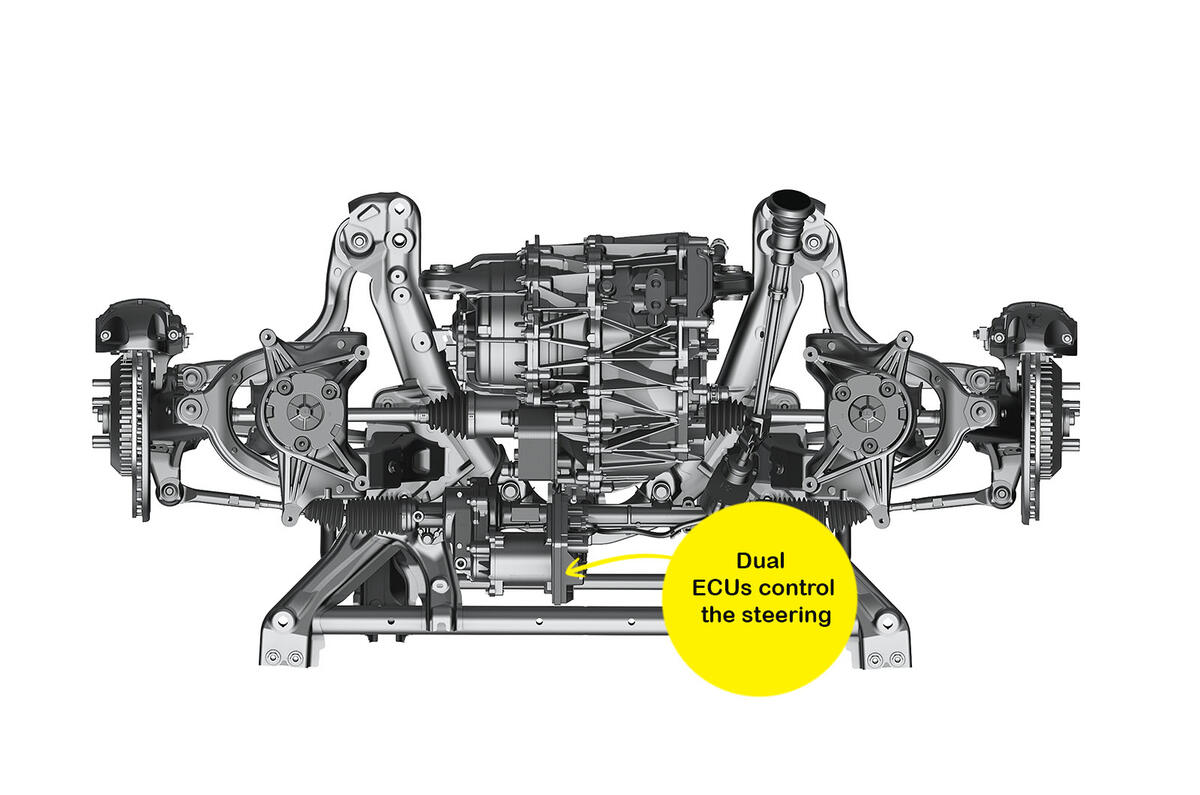

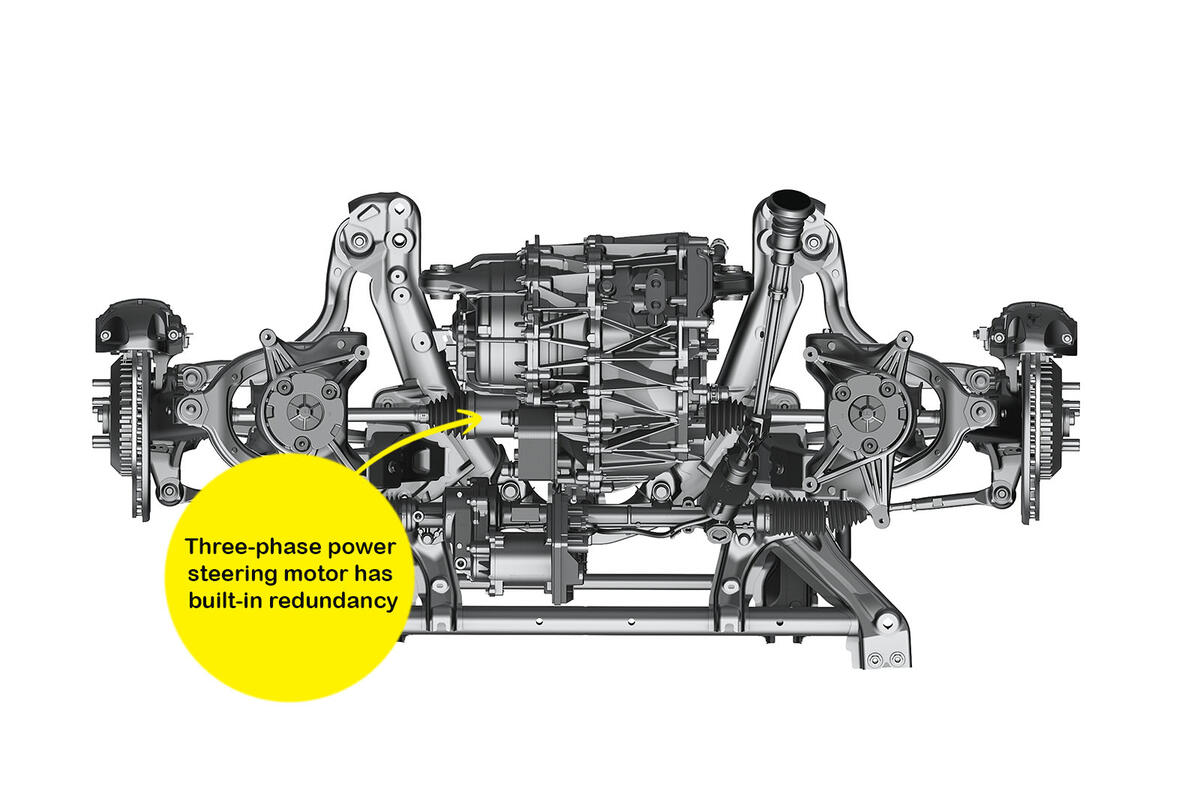

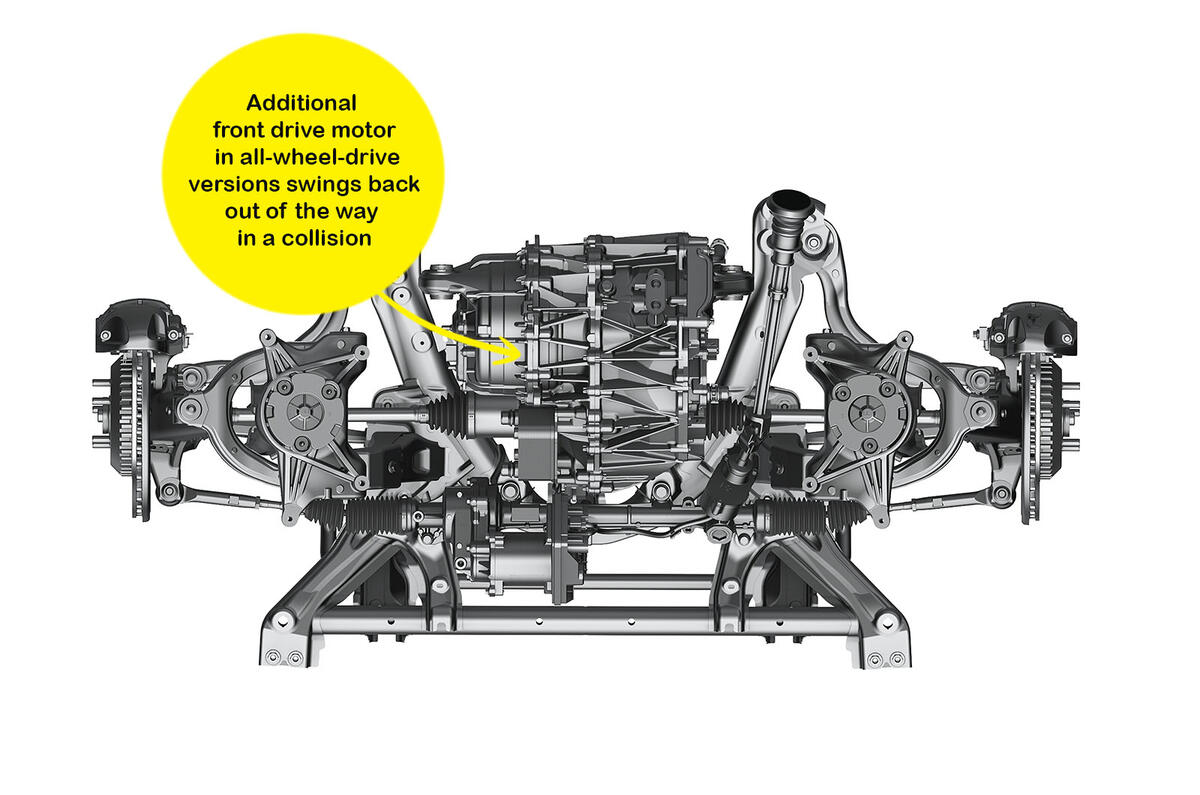

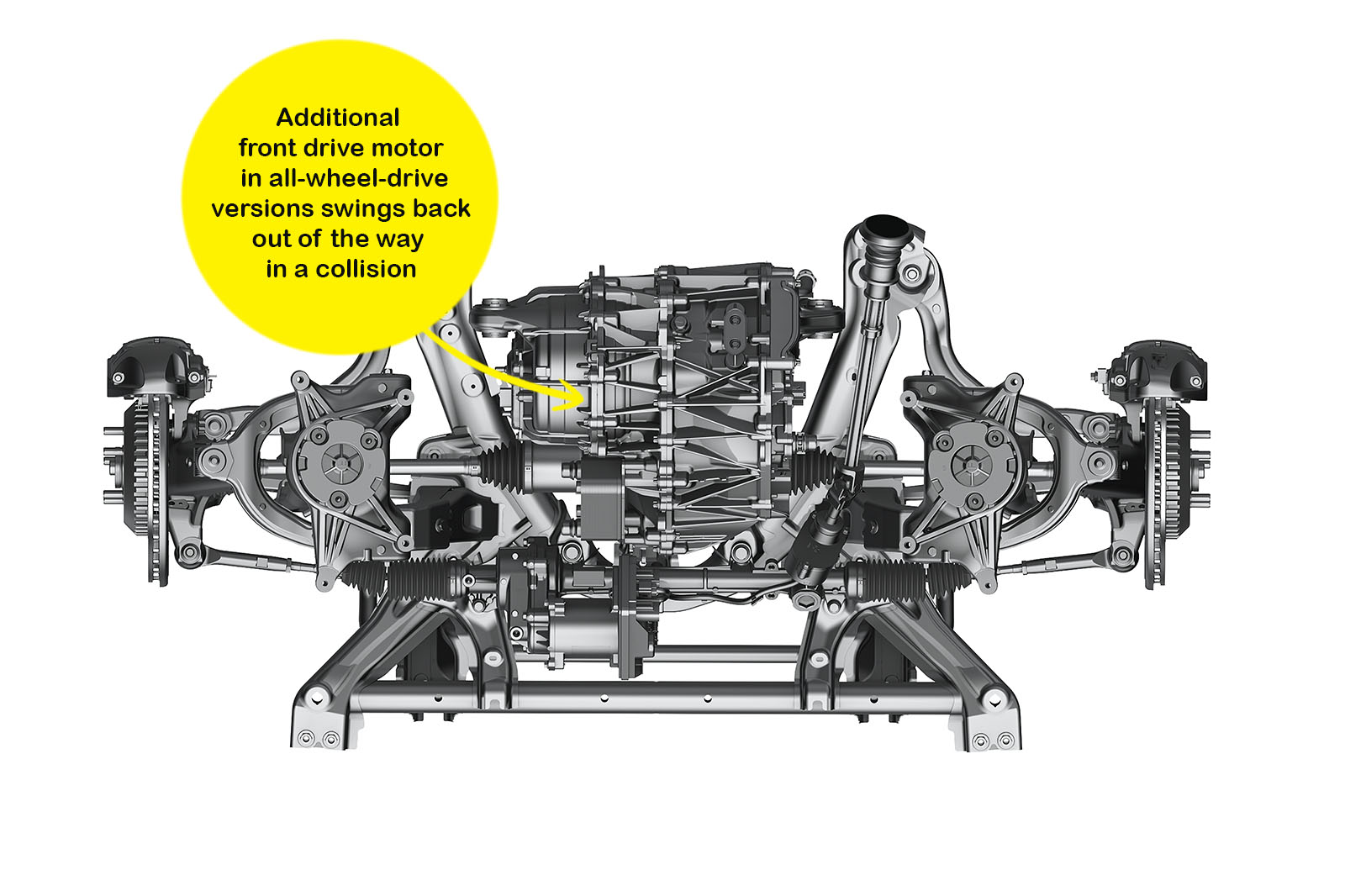

Each rear wheel has six degrees of freedom – five links and one damper, similar to a double wishbone – but the links have been split to give better control over the forces transmitted through the tyre’s contact patch. The front suspension has also been designed to provide maximum protection in the stringent, small-overlap frontal collision crash test.

Join the debate

Add your comment

Technically flawed!

Unfortunately the comments about cornering are jus wrong. Having a low CofG is advantagious in getting maximum cornering grip. The "build-up of vertical force through the outside tyres" does not help the grip because there is a corrisponding drop in the vertical load on the inside tyres and because of the non-linear relationship between tyre load and lateral grip the lateral load transfer reduces cornering capability. If this were otherwise performance car designers have been getting it wrong for over a century which they haven't.

Hopefully this rubbish didn't originate from the Tesla engineers or they really are in trouble!

Cost of insurance?

With so many parts designed to snap, crack or pop in an accident, the premiums are likely to be quite high for many drivers. And of course, the supply of these parts would have to follow suit lest there be garage forecourts full of Model 3s waiting for sacrificial links to arrive from the USA...

And another whinge: why should drivers pay so much for a car with a design life of 150K miles?

It is undoubtedly 'clever' but expensive ideas aren't necessarily good sellers: remember the Citroen hydraulic suspensions?

yvesferrer wrote:

The components are designed to break in order to protect the occupants during a high-impact crash. Doesn't matter if it's a Tesla or a Toyota, the insurance makes no difference if the car is a complete write-off.

yvesferrer wrote:

I doubt thats what they meant, by stating the discs last the life of the car, 150k miles, I'm sure they dont mean the cars life expectancy is only 150k. Mind you what actual life expectancy do modern ice cars actually have? What is a good life for an engine or gearbox? (What do manufacturers consider their products life to be I wonder.) Loads expire early and get no manufacturer support whilst some seemingly last forever. Batteries on hybrids were expected to last around 8 yrs or so but are going strong, way beyond that and have dropped in price, my crz replacement nimh battery is about £800, not far off a turbo on a tdi, but is still going strong and according to honda, hardly ever needing replacement, so it may not all be doom and gloom for an old/high mileage bev.

That all these steps tesla are taking is nothing new to other manufacturers, it does show that tesla are engineering and developing their cars properly when so many think otherwise.

Suspension sound like a weak link

how will it cope with the UKs potholed roads that knacker suspension that isnt designed to break, good luck with suspension that is..