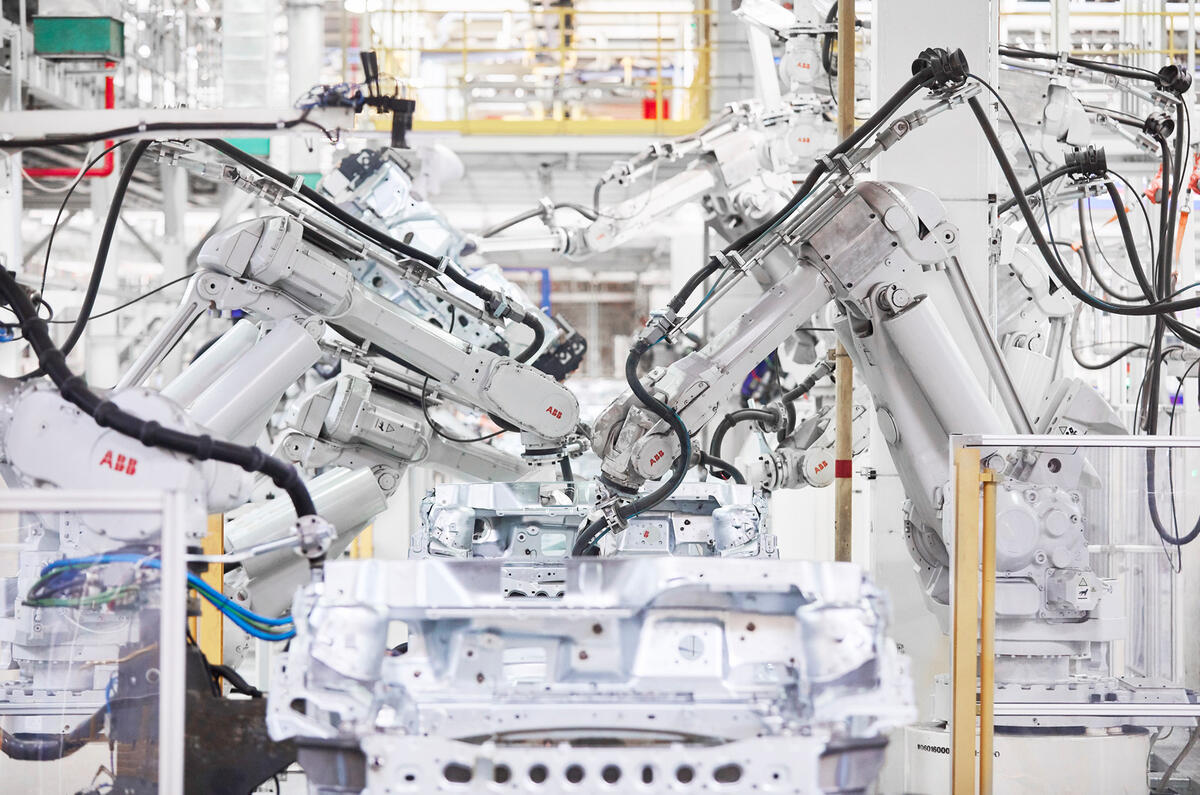

A radical reshaping of automotive production lines, to include flexible manufacturing cells, robotic guided vehicles and automated parts warehouses moved to trackside, are the key to making electric cars affordable, Europe’s second-biggest maker of robots, ABB, believes.

ABB is pushing a radical new production system that abandons the traditional assembly/trim line, with its dozens of sequential assembly stations, in favour of multiple flexible manufacturing cells between which vehicles and parts bins are hauled on trolleys by automated mobile robotic vehicles.

Join the debate

Add your comment

Interesting. The manufacturer implies this is the way to reduce the price of electric vehicles but we've been told time and time again that the more electric vehicles that are produced, the unit cost will come down. So when factories are only producing electric vehicles and they've replaced the manual workers with these robots, we can expect the price to fall? If that's true it'll be the only damned thing to go down in price.

I'll predict prices of electric vehicles will either steady or increase further still.

If you want to know what the car factory of the future will look like go and visit a Tesla Gigafactory. VW's Herbert Diess has already admitted Tesla's Giga Shanghai can build a Model 3 in a third of the time it takes VW to build an ID3 and Giga Berlin will be even faster.

I am curious what the the repairability of these new Teslas will be like with such enormous one piece castings?

These one piece castings are enormously strong. Any crash which will right-off a Tesla Model Y will right off a conventionally constructed vehicle.

Not quite sure how it is possible to write this article with no reference to Arrival ?

i know they're not making cars yet (or anything yet some might say) but this is their big manufacturing pitch with their micro-factories, surely.