British tech start-up Ionetic, established in January this year, has revealed a new battery pack design platform that it claims is much more cost- and space-efficient than off-the-shelf solutions.

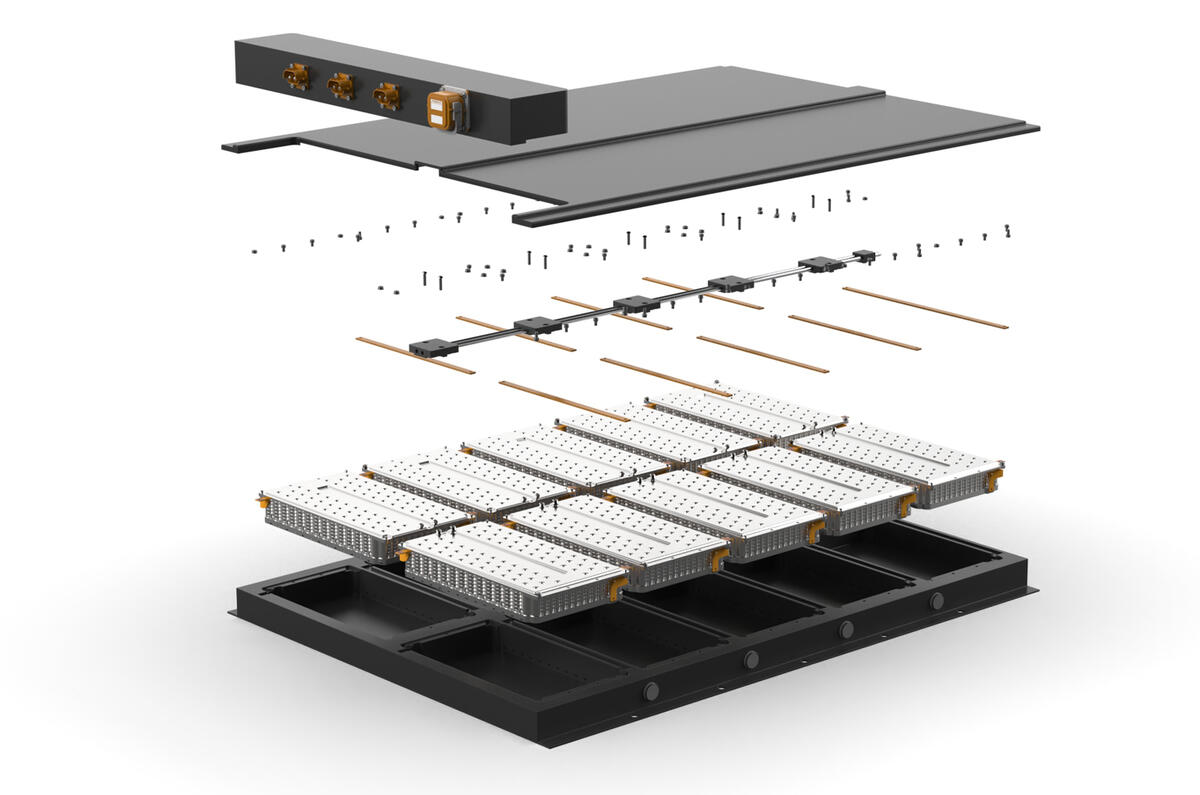

The company’s software automatically generates a battery pack design based around a series of adjustable parameters, using an architecture similar to that in the Tesla Model 3.

Add your comment