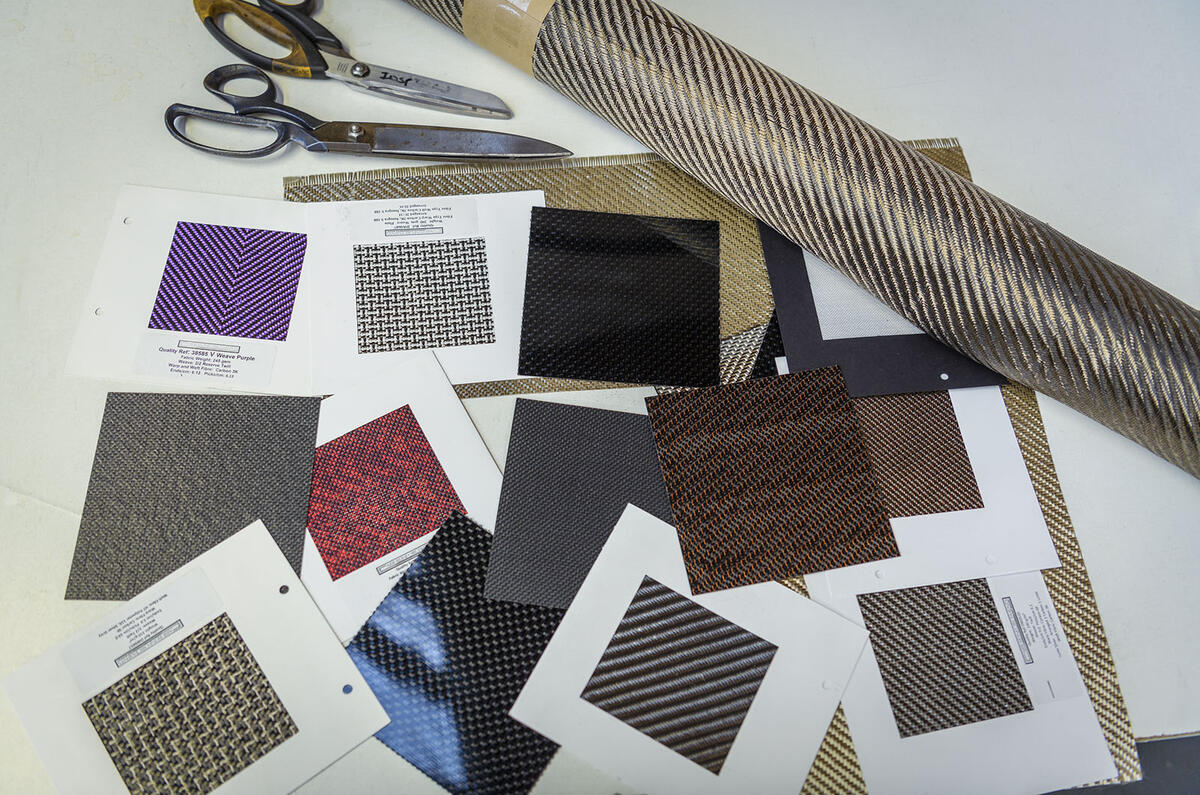

As an allegory for the automotive industry in the north of England, Carr Reinforcements is perfect. Based in an historic cotton mill on the edge of Burnley, it won a tender in 1962 from the Royal Aerospace Establishment to prove carbonfibre threads could be woven into sheets, thereby launching a new cutting-edge composite industry for which Formula 1, the aerospace industry and many others owe a debt of gratitude.

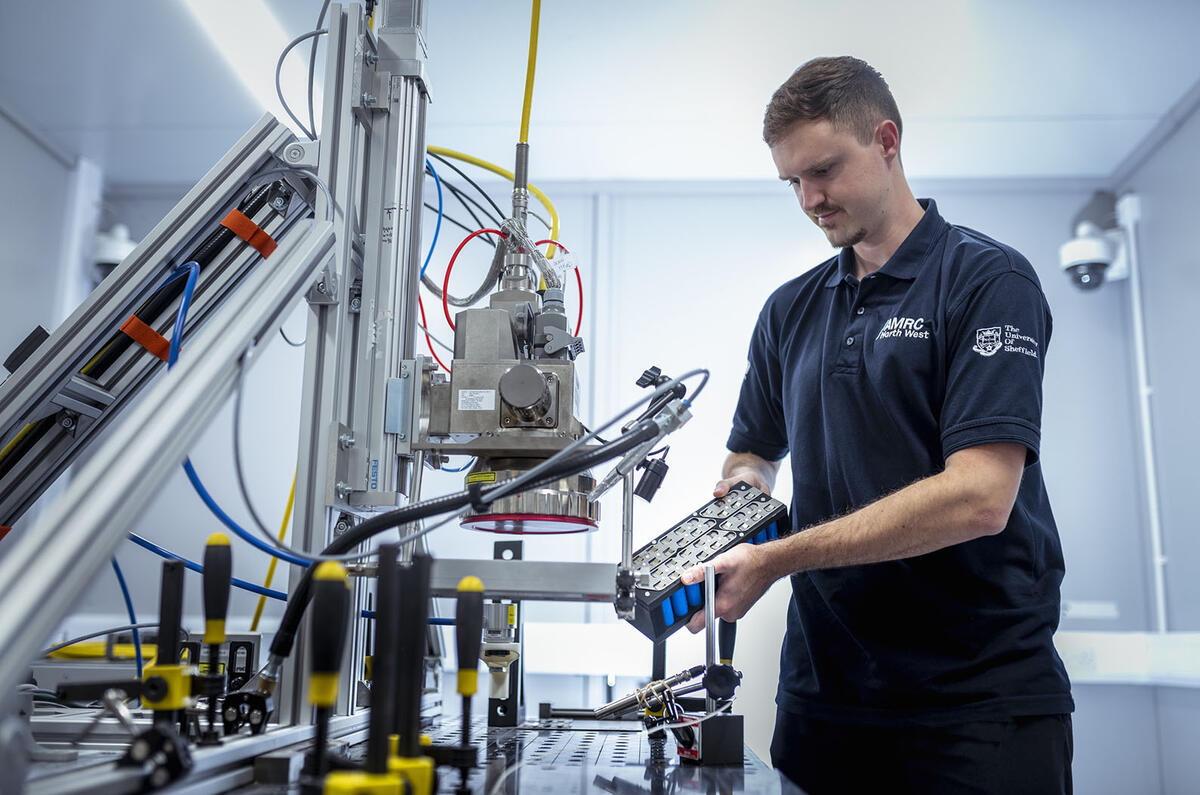

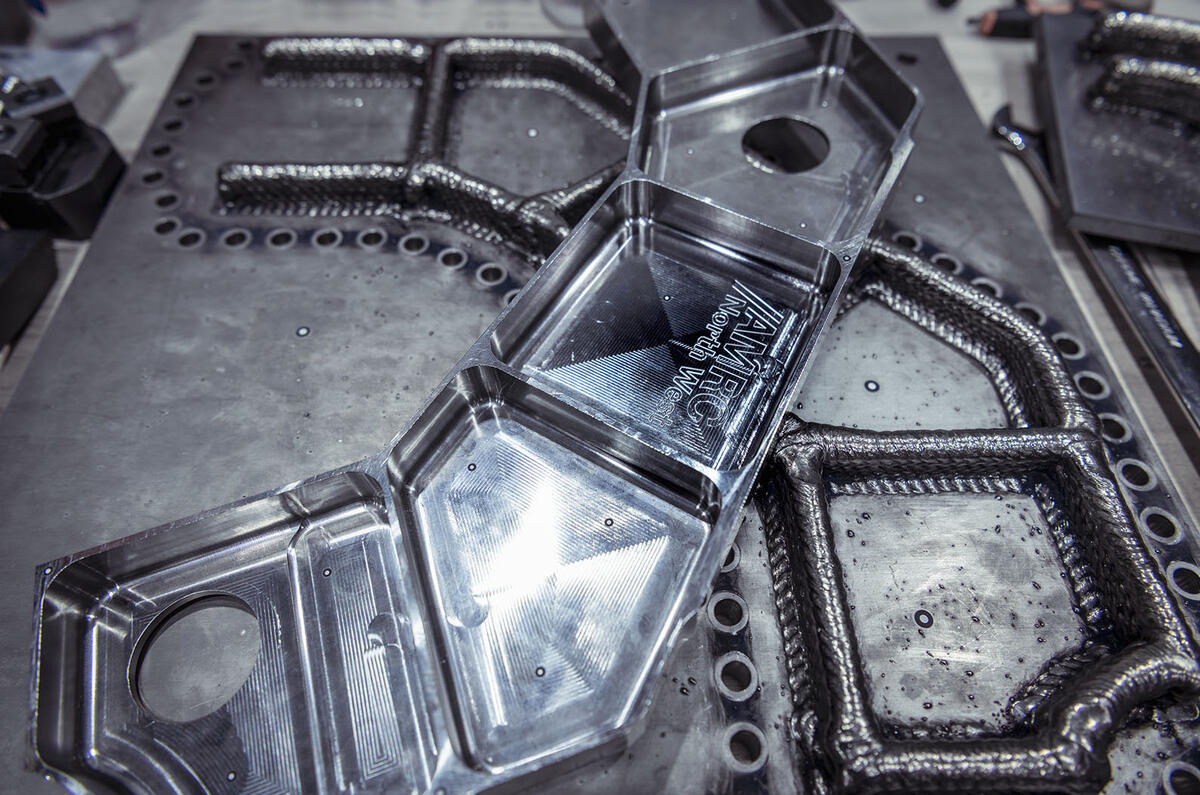

Today, Carr Reinforcements is working on new formulations of carbon weave based on basalt, an igneous rock that can withstand extreme high temperatures up to 1500deg C, properties that Mercedes-Benz is testing for lightweight and fireproof commercial vehicle battery casings.

Add your comment