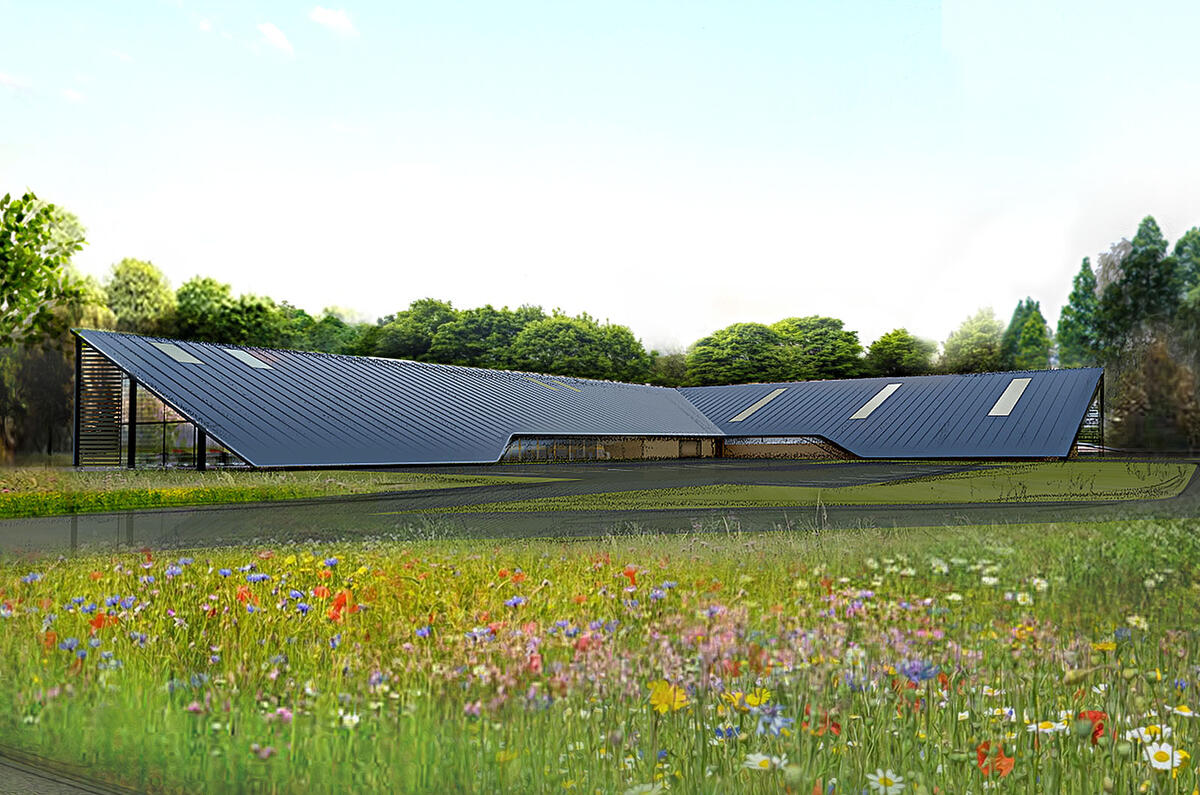

Ariel will build a factory close to its current Somerset base as it moves to expand its operations.

The new factory will be located to the east of Crewkerne – just off the A303 – on a 43-acre site that was recently acquired by the Atom maker after five years of negotiation.

Add your comment