Hydrogen versus battery power for cars is a debate that polarises opinion. But the potential use of hydrogen in fuel cell systems goes way beyond passenger vehicles.

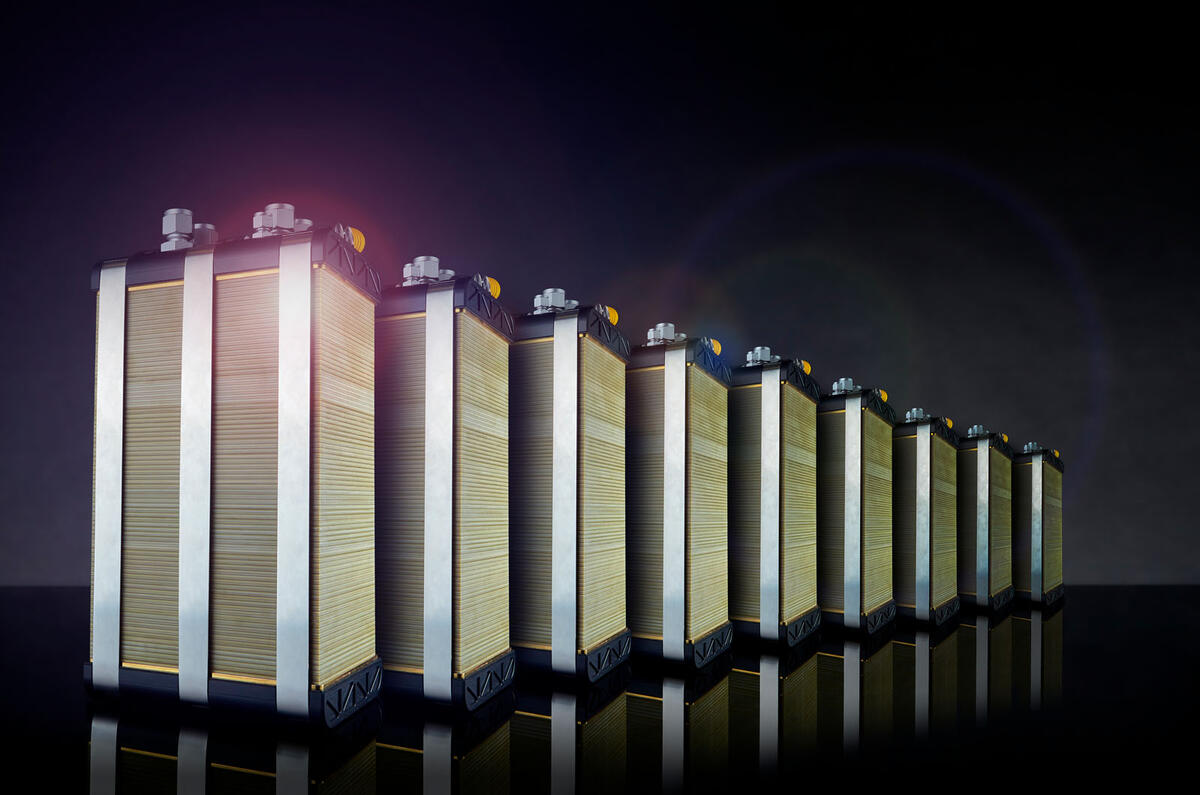

Bramble Energy was founded in 2016 as a spin-off from work at University College London and Imperial College by Tom Mason, Dan Brett and Anthony Kucernak. The three scientists are co-inventors of a revolutionary method of making fuel cells called Printed Circuit Board Fuel Cell (PCBFC), which cuts the time of making a bespoke fuel cell system from 14 -16 months to 10 -30 days.

Join the debate

Add your comment

The company, being a relatively new start-up is burning through millions of pounds at a rapid rate, it will be interesting to see if things improve in the next accounts.